|

|||

|

|

|||

| ||||||||||

|

|

material. The rack and pinion in figure 10-17, view C,

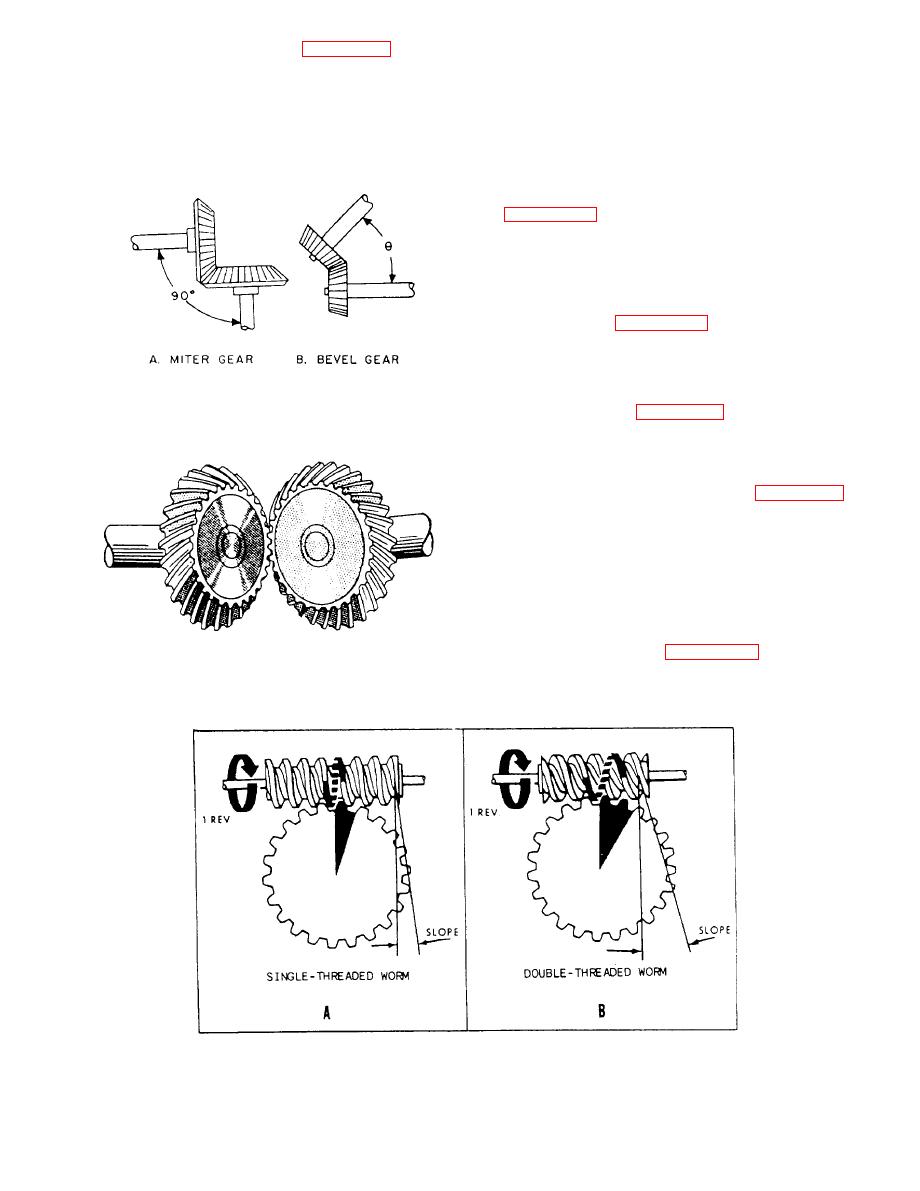

Bevel Gears

are both spur gears. The rack may be considered as a

So far, most of the gears you have learned about

piece cut from a gear with an extremely large radius.

transmit motion between parallel shafts. But when

The rack-and-pinion arrangement is useful in

shafts are not parallel (at an angle), another type of

changing rotary motion into linear motion.

gear is used--the bevel gear. This type of gear can

connect shafts lying at any given angle because they

can be beveled to suit the angle.

bevel gear-the miter gear. A pair of miter gears is

used to connect shafts having a 90-degree angle,

which means the gear faces are beveled at a 45-degree

angle.

You can see in figure 10-18, view B, how bevel

gears are designed to join shafts at any angle. Gears

cut at any angle other than 45 are called just plain

bevel gears.

The gears shown in figure 10-18 are called straight

bevel gears because the whole width of each tooth

comes in contact with the mating tooth at the same

time. However, some spiral level gears have teeth cut

so as to have advanced and trailing ends. Figure 10-19

is an illustration of spiral bevel gears. They have the

same advantages as other spiral (helical) gears--less

lost motion and smoother, quieter operation.

Worm Gears

Worm gears and worm gear-worm wheel

combinations, like those in figure 10-20, have many

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |