|

|||

|

Page Title:

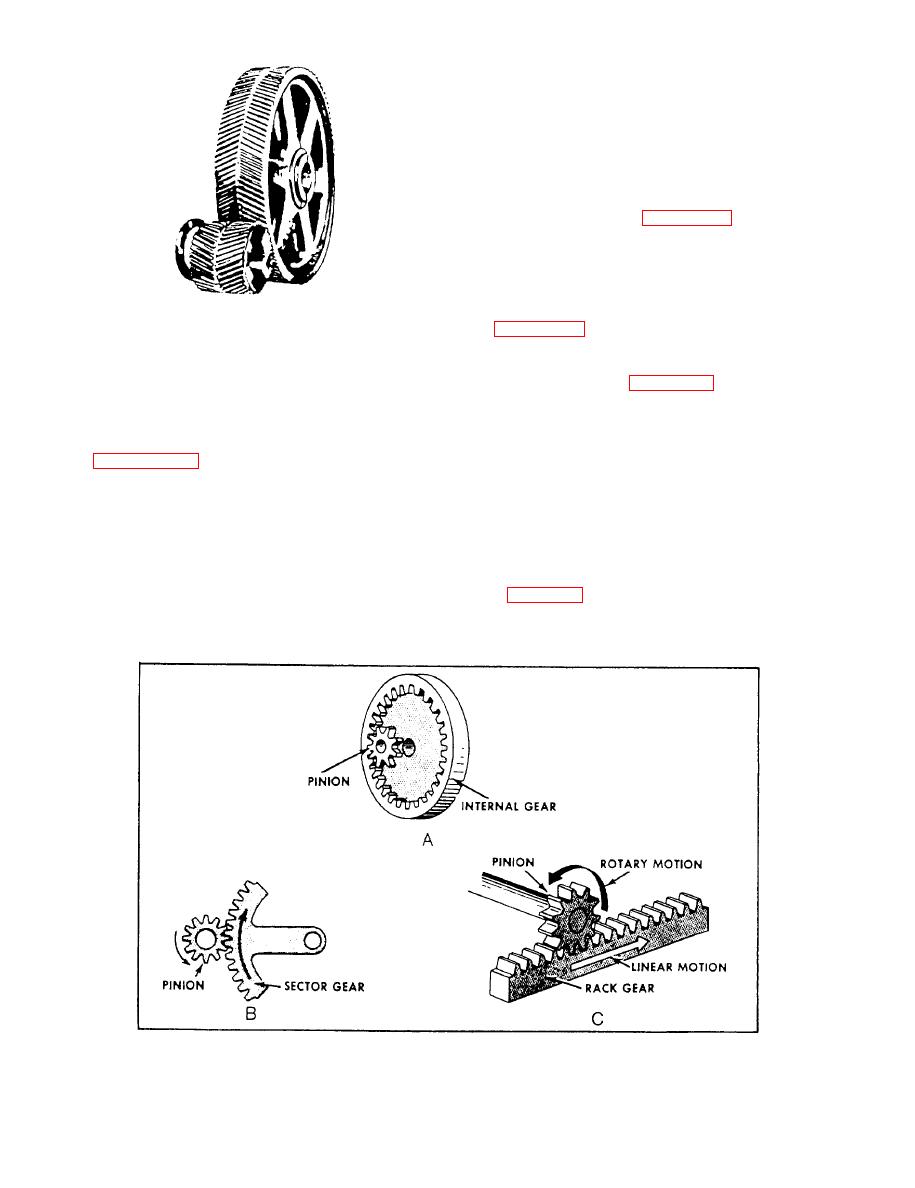

Figure 10-16.--Herringbone gears. |

|

||

| ||||||||||

|

|

contact. This kind of meshing action keeps the gears

in constant contact with one mother; therefore, less

lost motion and smoother, quieter action is possible.

One disadvantage of this helical spur gear is the

tendency of each gear to thrust or push axially on its

shaft. A special thrust bearing must be put at the end

of the shaft to counteract this thrust.

Thrust bearings are not needed if herringbone

gears like those shown in figure 10-16 are used. Since

the teeth on each half of the gear are cut in opposite

directions, each half of the gear develops a thrust that

counterbalances that of the other half. You'll find

herringbone gears used mostly on heavy machinery.

in common use.

In helical gears, the teeth are cut slantwise across

The internal gear in figure 10-17, view A, has teeth

the face of the gear. One end of the tooth, therefore,

on the inside of a ring, pointing inward toward the axis

lies ahead of the other. In other words, each tooth has

of rotation. An internal gear is always meshed with an

a leading end and a trailing end. A look at these gears

external gear, or pinion, whose center is offset from

in figure 10-15 will show you how they are

the center of the internal gear. Either the internal or

constructed.

pinion gear can be the driver gear, and the gear ratio

is calculated the same as for other gears-by counting

In the straight spur gears, the whole width of the

teeth.

teeth comes in contact at the same time. But with

helical (spiral) gears, contact between two teeth starts

Often only a portion of a gear is needed where the

first at the leading ends and moves progressively

motion of the pinion is limited. In this case, the sector

across the gear faces until the trailing ends are in

gear (fig. 10-17, view B) is used to save space and

Figure 10-17.--Gear arrangements.

10-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |