|

|||

|

Page Title:

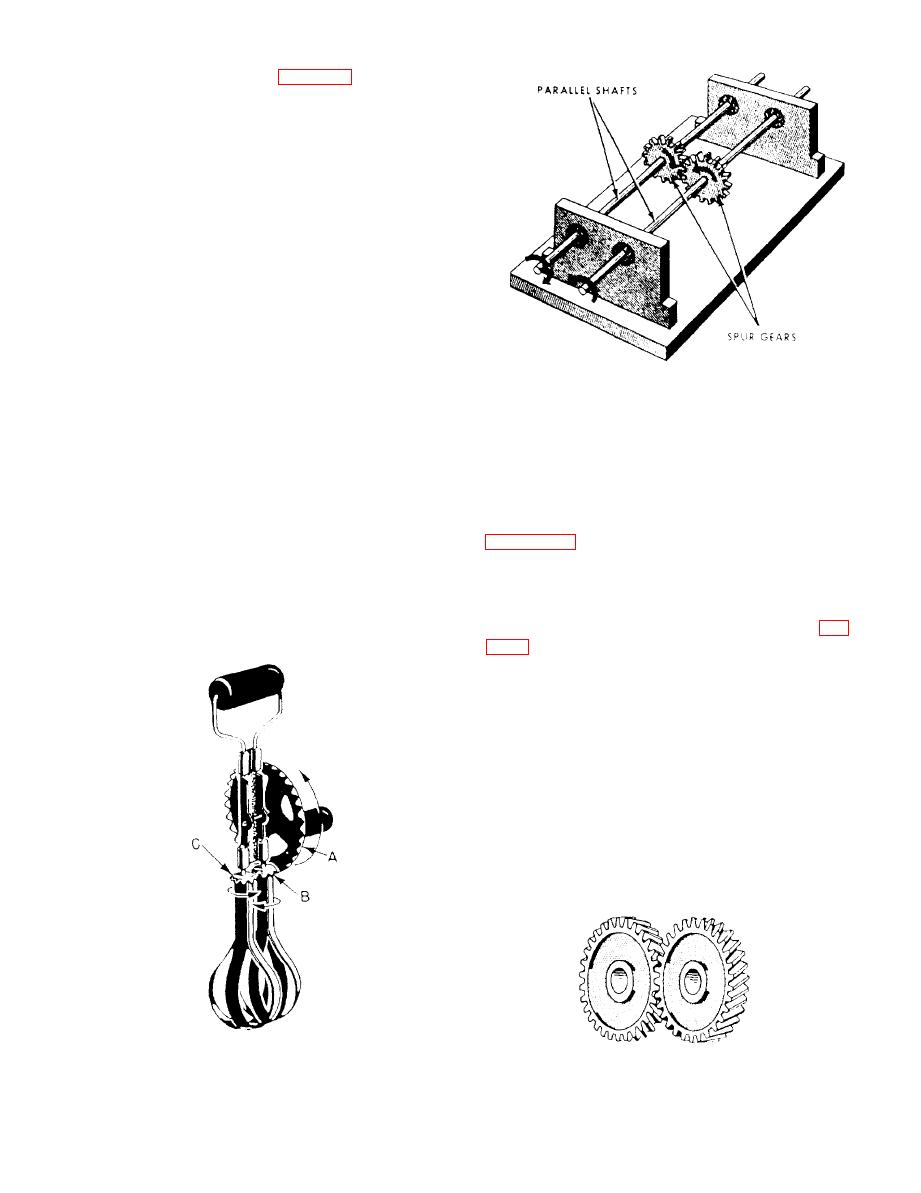

Figure 10-13.--A simple gear arrangement. |

|

||

| ||||||||||

|

|

A simple gear system that illustrates all of these

functions is the eggbeater (fig. 10-13). There are 32

teeth on gear A, which mesh with 8 teeth on gear B.

Notice the direction of rotation. Also notice that as

gear B turns in one direction, its teeth mesh with gear

C and cause C to revolve in the opposite direction. The

rotation of the crank handle has been transmitted by

gears A, B, and C to cause the beater blades to rotate.

Gears also can change the speed of the motion, as

was stated previously. Since gear A has 32 teeth and

gear B has only 8, one complete revolution of gear A

causes four complete revolutions of gear B. Therefore,

the ratio between A and B is 1:4. Since gear C also has

8 teeth, the ratio of B to C is 1:1. Therefore, the beater

blades revolve four times as fast as the crank handle.

Gears also can change the force of the applied

motion. Generally, any time a gear is used to increase

the speed of motion, the force at the output of the gear

Spur Gears

is reduced. Conversely, when the speed is reduced by

gears, the force at the output is increased.

When two shafts are not lying in the same straight

line but are parallel, motion can be transmitted from

TYPES OF GEARS

one to the other by spur gears. This setup is shown in

There are several types of gears used in

Spur gears are wheels with mating teeth cut in

mechanical assemblies. In the following paragraphs,

their surfaces so that one can turn the other without

we will discuss the spur, bevel, and worm gears.

slippage. When the mating teeth are cut so that they

are parallel to the axis of rotation (as shown in fig.

When two gears of unequal size are meshed

together, the smaller of the two is usually called a

pinion. By unequal size, we mean an unequal number

of teeth causing one gear to be of a larger diameter

than the other. The teeth, themselves, must be of the

same size in order to mesh properly.

The most commonly used type of spur gear is the

straight spur gear, but quite often you will run across

another type of spur gear called the helical spur gear.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |