|

|||

|

Page Title:

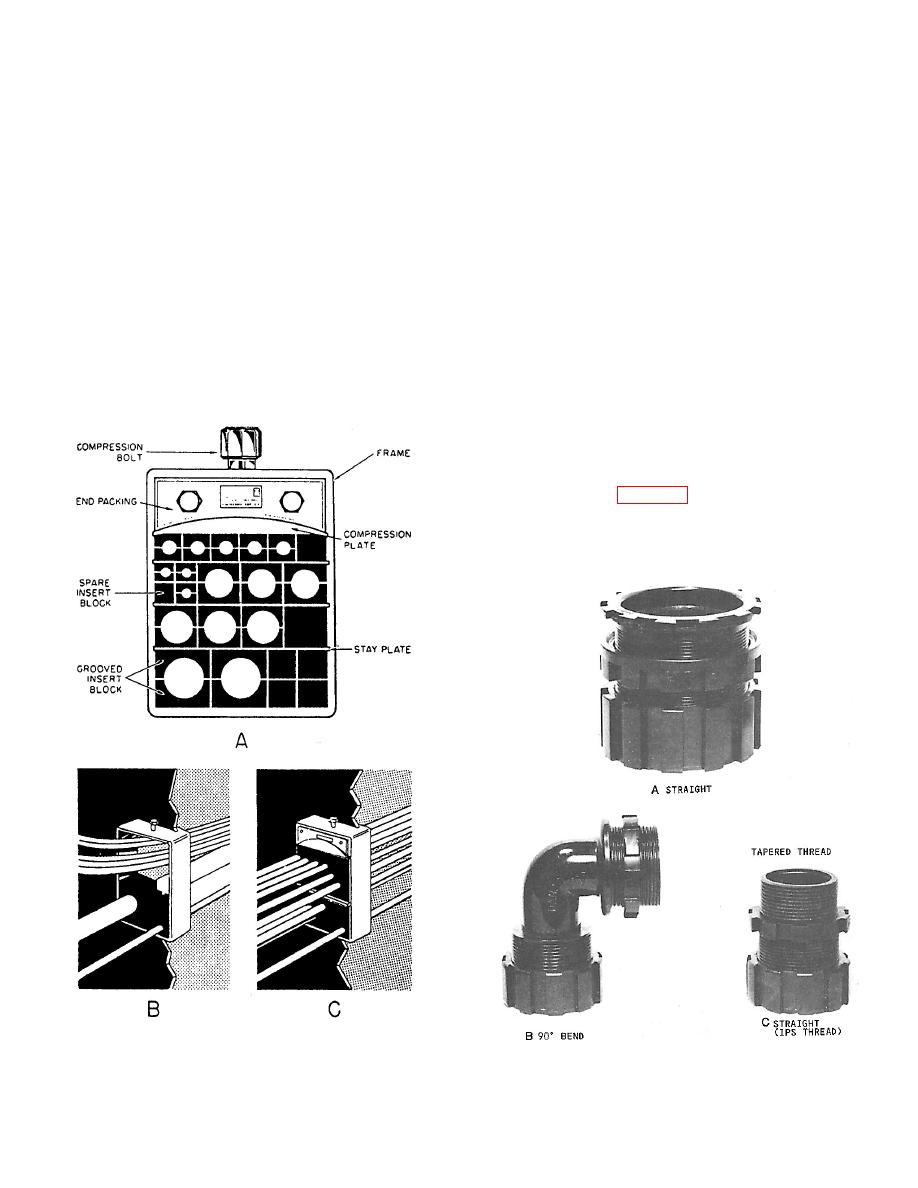

Figure 2-46.--Modular cable supports. |

|

||

| ||||||||||

|

|

up, a compression plate is inserted and tightened

Modular insert semicircular grooved twin half-

until there is sufficient room to insert the end

blocks are matched around each cable to form a single

packing.

block. These grooved insert blocks, which hold the

cables (along with the spare insert solid blocks), fill

up a cable support frame.

To complete the sealing of the blocks and cables,

the two bolts in the end packing are tightened evenly

until there is a slight roll of the insert material

During modular armored cable installation, a

around the end packing metal washers. This

sealer is applied in the grooves of each block to seal

indicates the insert blocks and cables are sufficiently

the space between the armor and cable sheath. The

compressed to form a complete seal. The compression

sealer penetrates the braid and prevents air passage

bolt is then backed off about one-eighth of a turn.

under the braid. A lubricant is used when the blocks

are installed to allow the blocks to slide easily over

each other when they are packed and compressed

When removing cable from modular supports, first

over the cable. Stay plates are normally inserted

tighten down the compression bolt. This pushes the

between every completed row to keep the blocks

compression plate further into the frame to free the

positioned and to help distribute compression evenly

split and packing. Then remove this end packing by

through-out the frame. When a frame has been built

loosening the two bolts that separate the metal

washers and the end packing pieces. Back off the

compression bolt, loosening the compression plate.

Then remove this plate, permitting full access to the

insert blocks and cables.

Stuffing Tubes

Stuffing tubes (fig. 2-47, views A, B, and C) are

used to provide for the entry of electric cable into

splashproof, spray tight, submersible, and explosion-

proof equipment enclosures. Cable clamps,

12.78

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |