|

|||

|

|

|||

| ||||||||||

|

|

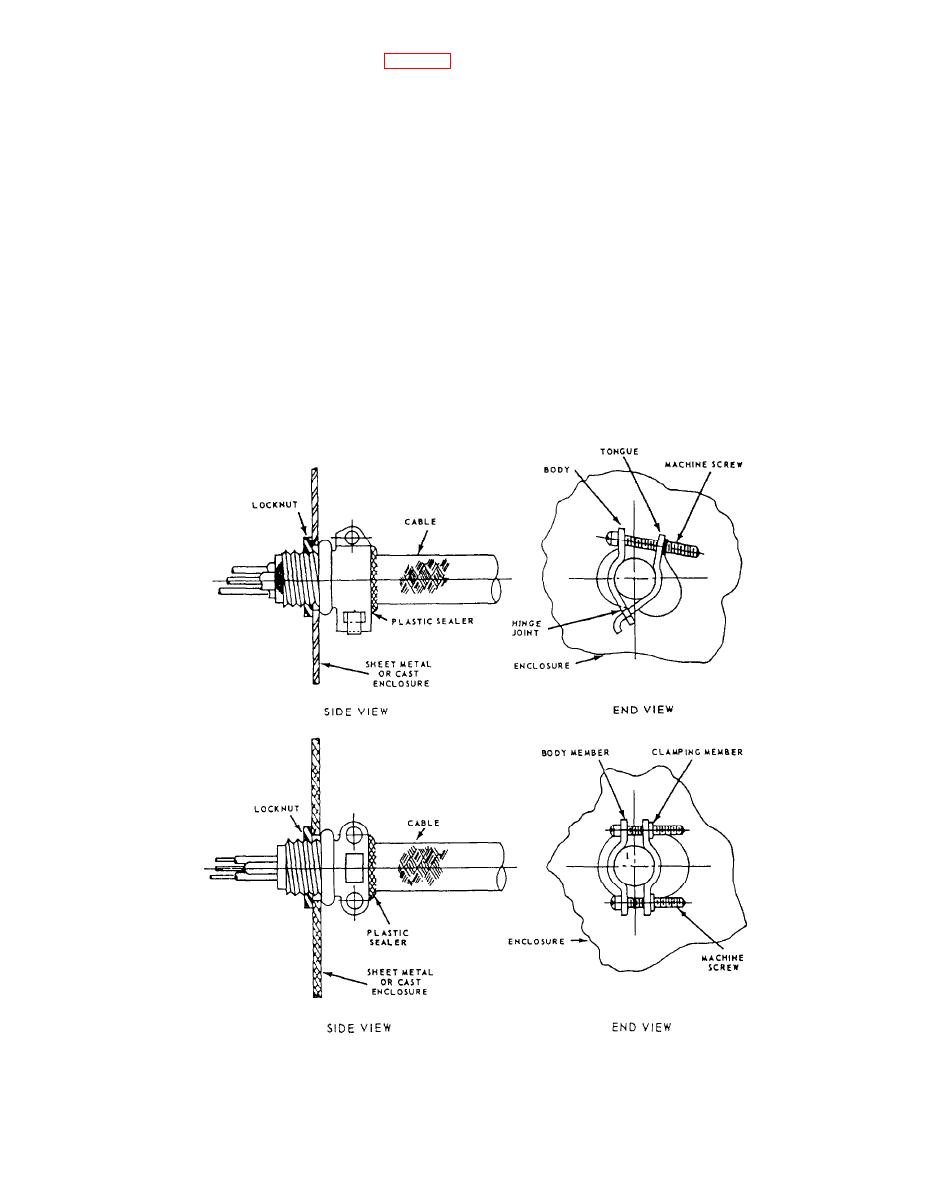

Stuffing tubes are made of nylon, steel, brass, or

commonly called box connectors (shown in fig. 2-48),

aluminum alloys. Nylon tubes have very nearly

may be used for cable entry into all other types of

replaced metal tubes for cable entry to equipment

equipment enclosures. However, top entry into these

enclosures.

enclosures should be made dripproof through stuffing

tubes or cable clamps sealed with plastic sealer.

The nylon stuffing tube is lightweight, positive-

sealing, and noncorrosive. It requires only minimum

Below the main deck, stuffing tubes are used for

maintenance for the preservation of watertight

cable penetrations of watertight decks, watertight

integrity. The watertight seal between the entrance to

bulkheads, and watertight portions of bulkheads that

the enclosure and nylon body of the stuffing tube is

are watertight only to a certain height. Above the main

made with a neoprene O-ring, which is compressed by

deck, stuffing tubes are used for cable penetrations of

a nylon locknut. A grommet-type neoprene packing is

(1) watertight or airtight boundaries; (2) bulkheads

compressed by a nylon cap to accomplish a watertight

designed to withstand a waterhead; (3) that portion of

seal between the body of the tube and the cable. Two

bulkheads below the height of the sill or coaming of

slip washers act as compression washers on the

compartment accesses; (4) flametight or gastight or

watertight bulkheads, decks, or wiring trunks within

grommet as the nylon cap of the stuffing tube is

tightened. Grommets of the same external size, but

turrets or gun mounts; and (5) structures subject to

with different sized holes for the cable, are available.

sprinkling.

2-44

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |