|

|||

|

Page Title:

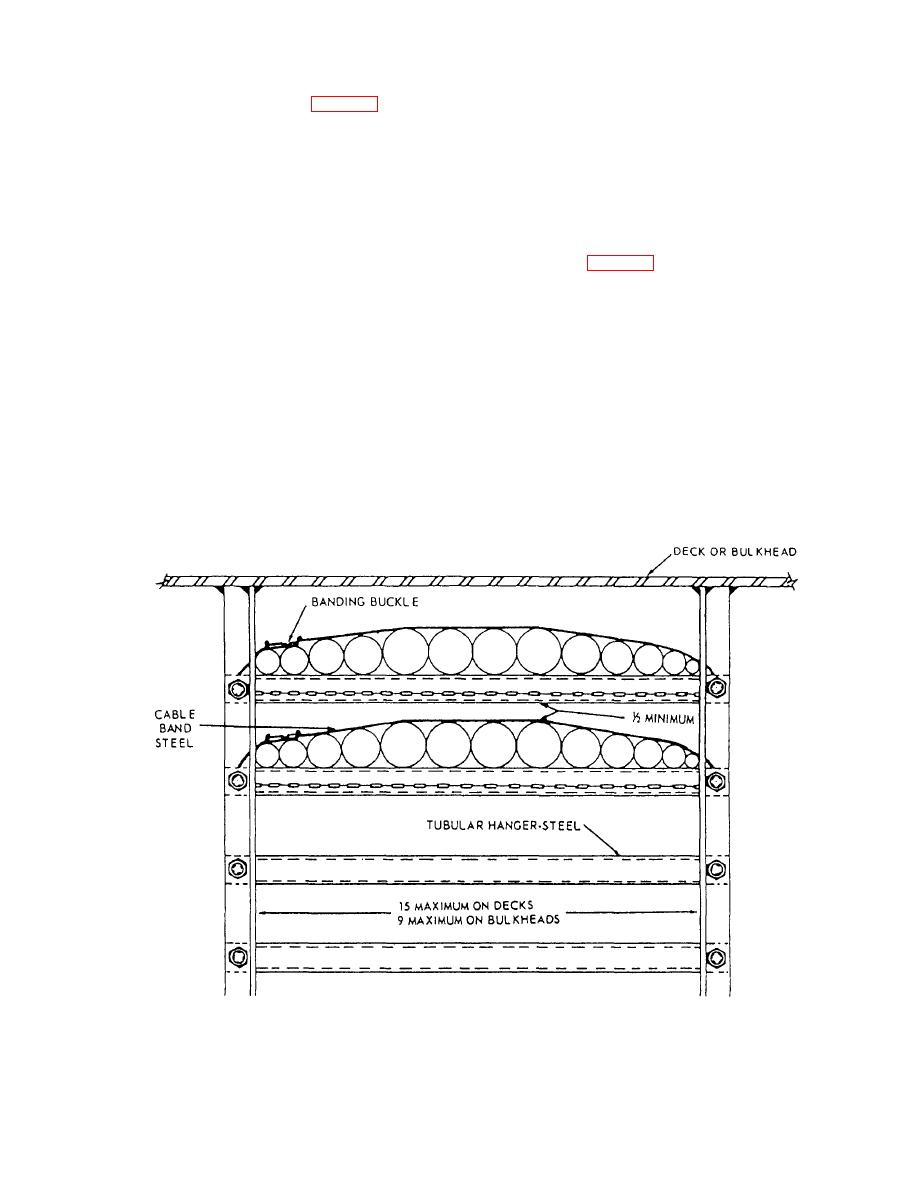

Figure 2-45.-Cables installed in a cable rack. |

|

||

| ||||||||||

|

|

Cables must be supported so the sag between

CABLE RACK.-- A more complex cable support

supports, when practicable, will not exceed 1 inch.

is the cable rack, which consists of the cable hanger,

Five rows of cables may be supported from an

cable strap, and hanger support (fig. 2-45).

overhead in one cable rack; two rows of cables may

Banding material is five-eighths of an inch wide

be supported from a bulkhead in one cable rack. As

many as 16 rows of cables may be supported in main

and may be zinc-plated steel, corrosion-resistant steel,

cableways, in machinery spaces, and boiler rooms.

or aluminum, depending on the requirements of the

Not more than one row of cable should be installed on

installation. For weather-deck installations, use

a single hanger.

corrosion-resistant steel band with copper-armored

MODULAR CABLE SUPPORTS.-- Modular

cables; zinc-coated steel with steel armor; and

cable supports (fig. 2-46) are installed on a number of

aluminum with aluminum armor.

naval ships. The modular method saves over 50

When applying banding material, apply one turn

percent in cable-pulling time and labor. Groups of

of banding for a single cable less than 1 inch in

cables are now passed through wide opened frames

instead of inserted individually in stuffing tubes. The

diameter. Apply two turns of banding for single cables

frames are then welded into the metal bulkheads and

of 1 inch or more in diameter and for a row of cables.

decks for cable runs.

Apply three turns of banding for partially loaded

hangers where hanger width exceeds the width of a

The modular method of supporting electrical

single cable or a single row of cable by more than

cables from one compartment to another is designed

to be fireproof, watertight, and airtight.

one-half inch.

2-42

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |