|

|||

|

Page Title:

Figure 2-9.--Zeroing a control transformer by the voltmeter method. |

|

||

| ||||||||||

|

|

2. De-energize the circuit and disconnect all other

connections from the differential leads. Set the volt-

meter on its 0- to 250-volt scale and connect as shown

in figure 2-8, view A. If a 78-volt supply is not available,

you may use 115 volts. If you use 115 volts instead of

78 volts, do not leave the unit connected for more than

2 minutes or it may overheat and may cause permanent

damage.

3. Energize the circuit, unclamp the differential's

stator, and turn it until the meter reads minimum. The

differential is now approximately on electrical zero.

De-energize the circuit and reconnect it as shown in

figure 2-8, view B.

4. Re-energize the circuit. Start with a high scale

on the meter and work down to the 0- to 5-volt scale to

protect the meter movement. At the same time, turn the

differential transmitter until a zero or null (minimum

voltage) reading is obtained. Clamp the differential

stator in this position, ensuring the voltage reading does

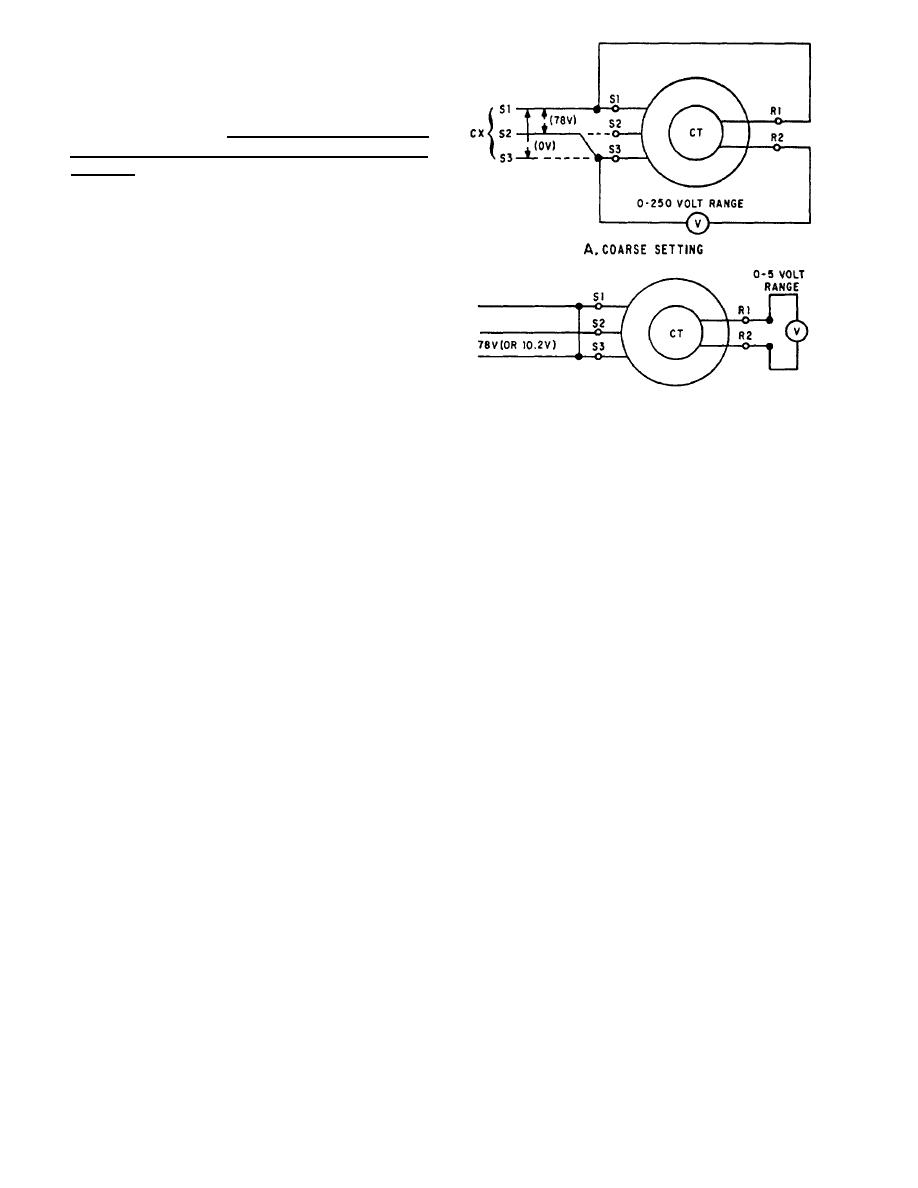

Figure 2-9.--Zeroing a control transformer by the voltmeter

not change, de-energize, and connect all leads for

method.

normal operation. This is the fine electrical zero position

of the differential.

ZEROING A CONTROL TRANSFORMER

exist for a control transformer (CT) to be on electrical

required to zero the CT, leave the S1 lead on, disconnect

zero. First, its rotor voltage must be minimum when

the S3 lead on the CT, and put the S2 lead (from CX) on

electrical zero voltages are applied to its stator. Second,

S3. This is necessary since 78 volts exist only between

turning the shaft of the CT slightly counterclockwise

S1 and S2 or S2 and S3 on a properly zeroed CX. Now

produces a voltage across its rotor in phase with the rotor

energize the circuit and turn the stator of the CT to obtain

voltage of the CX or TX, supplying excitation to its

a minimum reading on the 250-volt scale. This is the

stator. Electrical zero voltages, for the stator only, are

coarse or approximate zero setting of the CT.

the same as for transmitters and receivers.

4. De-energize the circuit, reconnect the S1, S2,

To zero a CT by the voltmeter method, use the

and S3 leads back to their original positions, and then

following procedure:

connect the circuit as shown in figure 2-9, view B.

1. Set the mechanism that drives the CT rotor to

5. Re-energize the circuit. Start with a high scale

zero or to its reference position. Also, set the transmitter

on the meter and work down to the 0-to 5-volt scale to

that is connected to the CT to zero or its reference

protect the meter movement. At the same time, turn the

position.

stator of the CT to obtain a zero or minimum reading on

the meter. Clamp down the CT stator, ensuring the

2. Check to ensure there is zero volts between S1

reading does not change. This is the fine electrical zero

and S3 and 78 volts between S2 and S3. If these voltages

position of the CT.

cannot be obtained, it will be necessary to rezero the

transmitter.

Zeroing Multispeed Synchro

NOTE: If 78 volts from the transmitter cannot be

Systems

used and an autotransformer is not available, use a

115-volt source. The CT should not be energized for

If multispeed synchro systems are used to

more than 2 minutes in this condition because it will

accurately transmit data, then the synchros within the

overheat and may cause permanent damage.

systems must be zeroed together. This is necessary

because these synchros require a common electrical

3. De-energize the circuit and connect the circuit

zero to function properly in a system.

as shown in figure 2-9, view A. To obtain the 78 volts

2-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |