|

|||

|

Page Title:

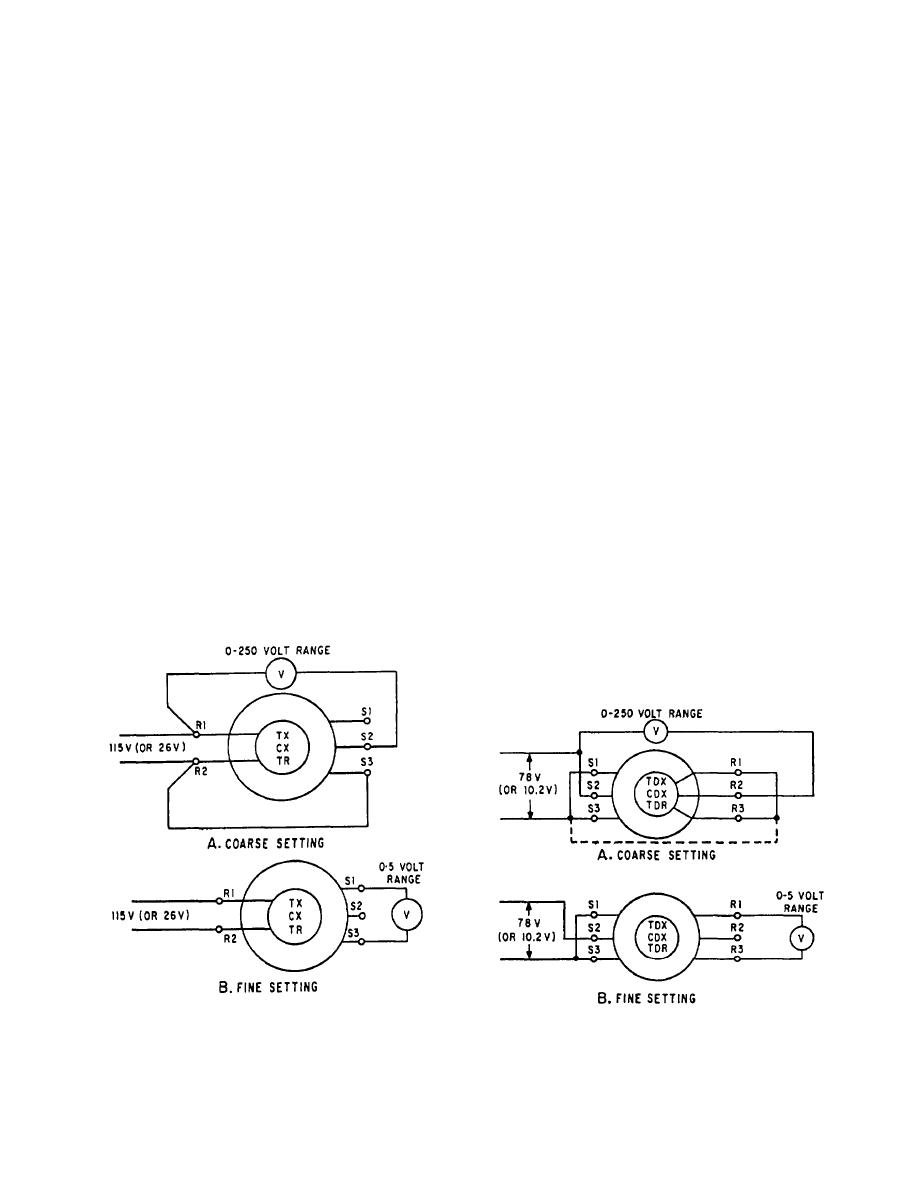

Figure 2-7.--Zeroing a transmitter or receiver by the voltmeter method. |

|

||

| ||||||||||

|

|

NOTE: Many synchro systems energize by

ZEROING TRANSMITTERS AND RECEIV-

individual switches. Therefore, be sure the synchro

ERS (VOLTMETER METHOD). A synchro

power is off before working on the connections.

transmitter, CX or TX, is zeroed if electrical zero

voltages exist when the device whose position the CX

3. Energize the synchro circuit and turn the stator

or TX transmits is set to its mechanical reference

or rotor until the meter reads about 37 volts (15 volts for

a 26-volt synchro). This is the coarse setting, and it

position. A synchro receiver, TR, is zeroed if, when

places the synchro at about electrical zero.

electrical zero voltages exist, the device actuated by the

receiver assumes its mechanical reference position. In a

4. De-energize the synchro circuit and connect the

receiver or other unit having a rotatable stator, the zero

meter as shown in figure 2-7, view B, using the 0- to

position is the same, with the added provision that the

5-volt scale.

unit to which the stator is geared is set to its reference

5. Re-energize the synchro circuit and adjust the

position. In the electrical zero position, the axes of the

rotor or stator for a null (minimum voltage) reading.

rotor coil and the S2 coil are at zero displacement and

This is the fine electrical zero position of the synchro.

the voltages measured between terminals S1 and S3 will

The common electrical zero position of a TX-TR

be minimum. The voltages from S2 to S1 and from S2

synchro system can be checked with a jumper. Put the

to S3 are in phase with the excitation voltage from R1

transmitter and receiver on zero and intermittently

to R2.

jumper S1 and S3 at the receiver. The receiver should

The following method may be used to zero

not move. If it does, the transmitter is not on zero and

transmitters and receivers:

should be checked again.

1. Carefully set the unit whose position the synchro

ZEROING DIFFERENTIAL SYNCHROS

transmits to its zero or mechanical reference position.

when it can be inserted into a system without intro-

2. De-energize the synchro circuit and disconnect

ducing a change in the system. In the electrical zero

the stator leads. Set the voltmeter to its 0- to 250-volt

position, the axes of coils R2 and S2 are at zero

scale and connect it into the synchro circuit as shown in

displacement. If a differential synchro requires zeroing,

figure 2-7, view A.

the following method may be used:

1. Carefully and accurately set the unit to be zeroed

to its zero or mechanical reference position.

Figure 2-8.--Zeroing differential synchros by the voltmeter

Figure 2-7.--Zeroing a transmitter or receiver by the voltmeter

method.

method.

2-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |