|

|||

|

Page Title:

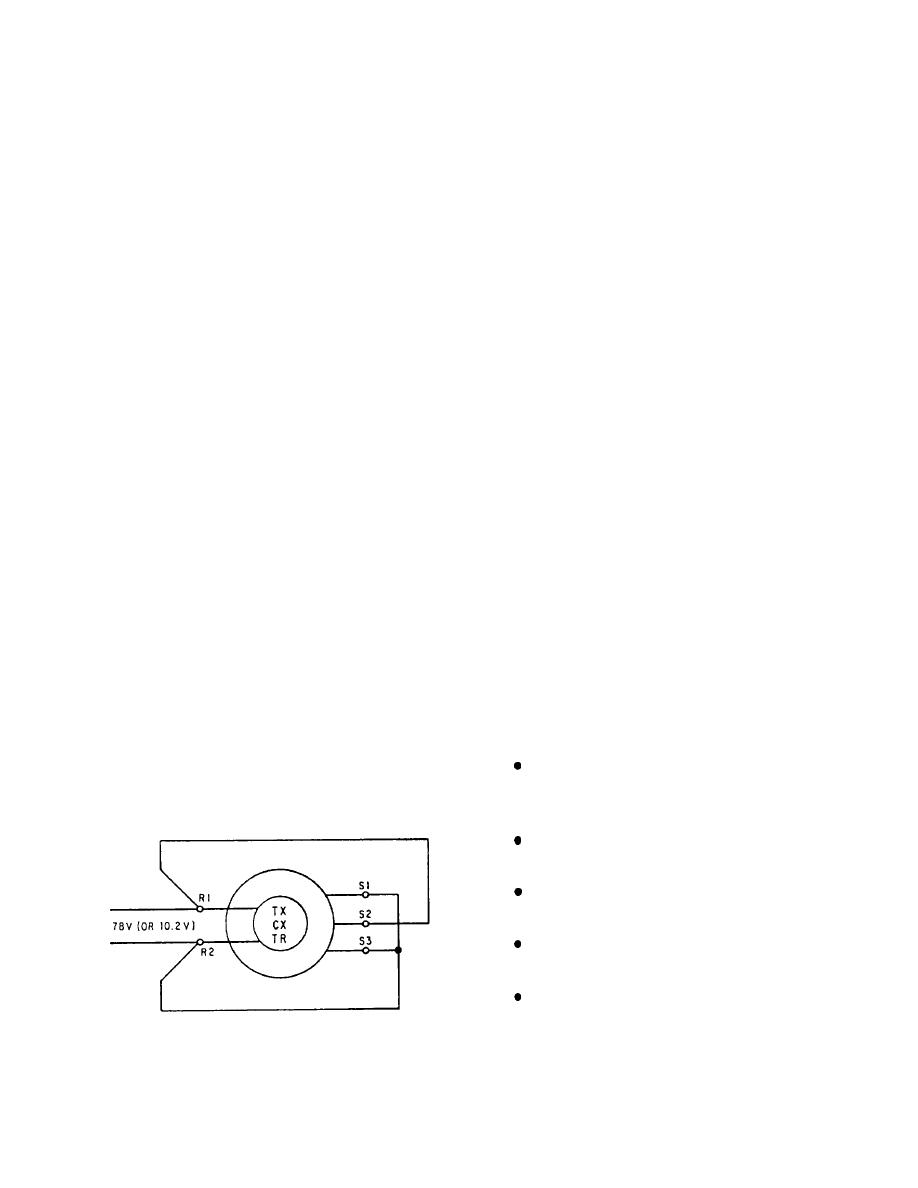

Figure 2-10.--Zeroing a synchro by the electrical lock method. |

|

||

| ||||||||||

|

|

holes into its frame, NEVER use pliers on the threaded

First, establish the zero or reference position for the

unit whose position the system transmits. Then, zero the

shaft, and NEVER use force to mount a gear or dial on

most significant synchro in the system and work down

the shaft.

to the least significant. For example, zero the coarse

In maintaining synchros, there are two basic rules

synchro, then the medium synchro, and finally the fine

to apply:

synchro. When zeroing these synchros, consider each

synchro as an individual unit and zero accordingly.

1. IF IT WORKS, LEAVE IT ALONE.

There are a few 3-speed synchro systems. These

2. IF IT GOES BAD, REPLACE IT.

systems require zeroing in an identical reamer as the

Shipboard synchro troubleshooting is limited to

dual-speed systems. First, zero the most significant

determining whether the trouble is in the synchro or in

synchro in the system and then work down to the least

the system connections. You can make repairs to the

significant.

system connections, but if something is wrong with the

Remember that all synchros in a system must have

unit, replace it.

a common electrical zero position.

Electrical Lock Method

SYNCHRO SIGNAL AMPLIFIER

The electrical lock method (although not as accurate

The reason for using synchro signal amplifiers is to

as the voltmeter method) is perhaps the fastest method

reduce the size of synchro transmitters. These smaller

of zeroing synchros. However, this method can be used

synchro transmitters are used in wind indicators and

only if the rotors of the units to be zeroed are free to turn

other sensing devices that are more accurate if there is

and the lead connections are accessible. For this reason,

only a small load on their outputs.

this method is usually used on the TR because, unlike

You should already know the operating principle of

transmitters, the TR shaft is free to turn.

the synchro signal amplifier. The input to the amplifier

To zero a synchro by the electrical lock method,

is from a small synchro transmitter or two small trans-

de-energize the unit, connect the leads, as shown in

mitters that give a coarse and a fine signal. The input

figure 2-10, and apply power. The synchro rotor will

signal controls a small servomotor. This servomotor

then quickly snap to the electrical zero position and lock.

drives one or more large synchros into a position cor-

As stated before, you may use 115 volts as the power

responding to the position of the input synchro. The

supply instead of 78 volts if the unit does not remain

connected for more than 2 minutes.

output from the large synchros is then used as needed to

drive several synchro receivers.

SYNCHRO MAINTENANCE AND

Synchro signal amplifiers must meet some or all of

TROUBLESHOOTING

the following operational requirements:

Synchro units require careful handling at all times.

Accept a low-current synchro signal, amplify the

NEVER force a synchro unit into place, NEVER drill

signal, and use the amplifier signal to drive large-

capacity synchro transmitters.

Isolate oscillations in a synchro load that may be

reflected from the input signal bus.

Permit operation of a 60- or 400-Hz synchro load

from either a 60-or 400-Hz synchro bus.

Provide multiple charnel output transmission of

a single-channel input signal.

Permit operation of a synchro load independent

of the input synchro excitation.

A block diagram of a synchro signal amplifier is

Figure 2-10.--Zeroing a synchro by the electrical lock method.

shown in figure 2-11.

2-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |