|

|||

|

Page Title:

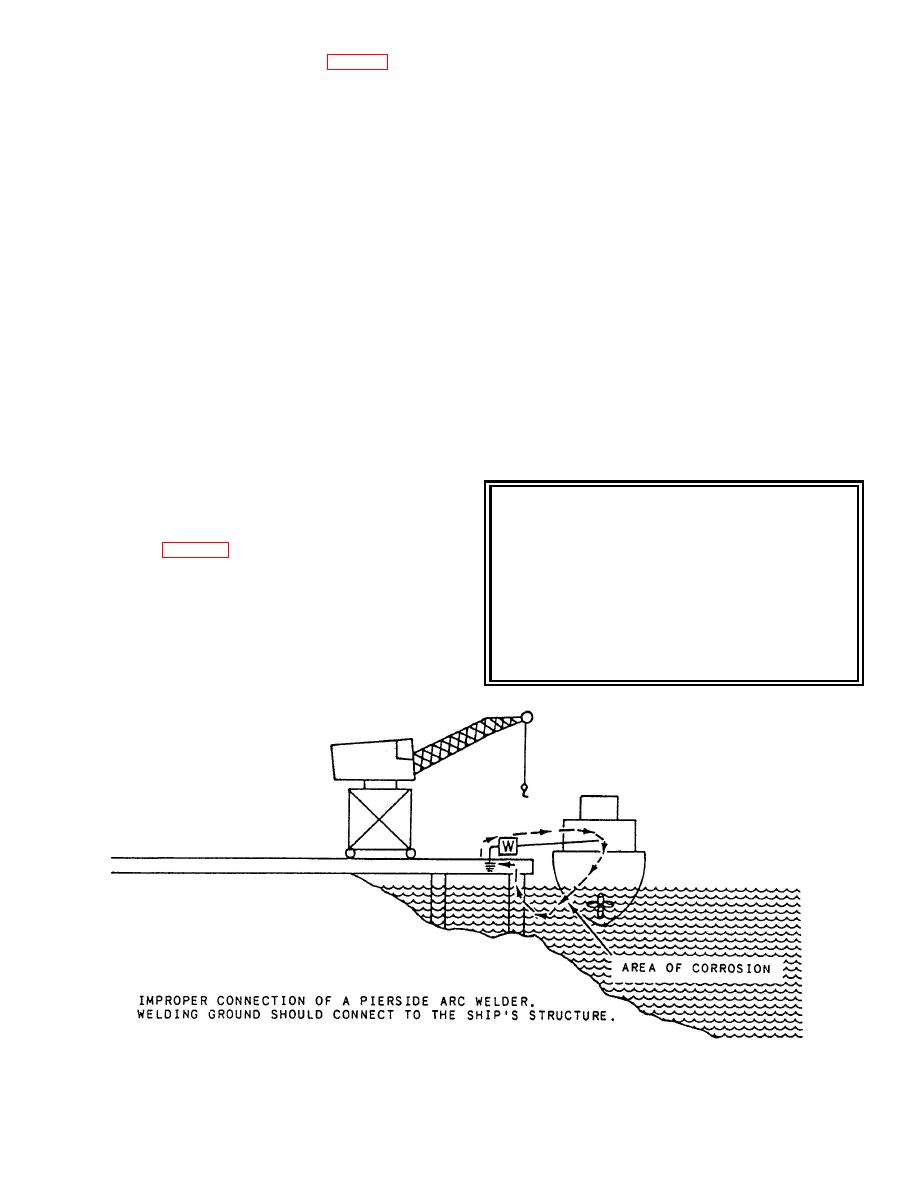

Figure 11-8.--Stray-current corrosion. |

|

||

| ||||||||||

|

|

welding machine is not correctly made (fig. 11-8) or no

TYPES OF SACRIFICIAL ANODES.-- The

return lead to the welder is connected, you could have

following is a list of sacrificial anodes:

current flow between the ship's hull and the pier,

Zinc

causing corrosion to form on the hull.

Aluminum

Seawater resistivity is the concentration of ions

Magnesium

in seawater, which acts as a resistance to current flow

between two dissimilar metals. Normal seawater gener-

Iron

ally has a nominal resistivity of 20 to 22 ohms/cm at a

Steel waster pieces

temperature of 20C (68F). In brackish or fresh water

this resistivity may vary.

Zinc Anodes.-- Zinc anodes are used for anodic

polarization on steel or aluminum surfaces. They have a

TYPES OF CATHODIC PROTECTION

half-cell potential of a negative 1.04 volts. They can be

either bolted or welded to the hull. Welding is the

There are two types of cathodic protection

preferred method because the anodes will have a secure

systems, the sacrificial anode and the impressed current.

electrical and mechanical attachment.

Each system will be addressed separately.

Aluminum Anodes.-- Aluminum anodes are

Sacrificial Anode System

currently being tested and evaluated by the Naval Sea

Systems Command (NAVSEA). The use of aluminum

The sacrificial anode system is based on the

anodes requires prior NAVSEA authorization and

principle that a more reactive metal, when installed

design review. It is also necessary to obtain guidance

near a less reactive metal and submerged in an

from NAVSEA before preparing a cathodic protection

electrolyte such as seawater, will generate a potential of

system design using aluminum anodes.

a sufficient magnitude to protect the less reactive metal.

In this process, the more reactive metal is sacrificed.

CAUTION

Sacrificial anodes attached to a ship's hull slowly oxidize

Do not use magnesium anodes on

and generate a current (see the electrochemical

aluminum hulls. Production of an

corrosion cell in fig. 11-6 that protects the hull and its

alkaline (basic corrosion product) may

appendages). This system does not have an onboard

lead to serious corrosion of the

control of protecting current, and depends on the limited

aluminum metal structure. Aluminum is

current output of the anode. This type of system

referred to as an amphoteric material

requires anode replacement on a fixed schedule (usually

because it is subject to deterioration by

every 3 years on naval ships). The system is rugged and

simple, requires little or no maintenance, and always

both

acid

and

basic

solutions.

protects the ship.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |