|

|||

|

|

|||

| ||||||||||

|

|

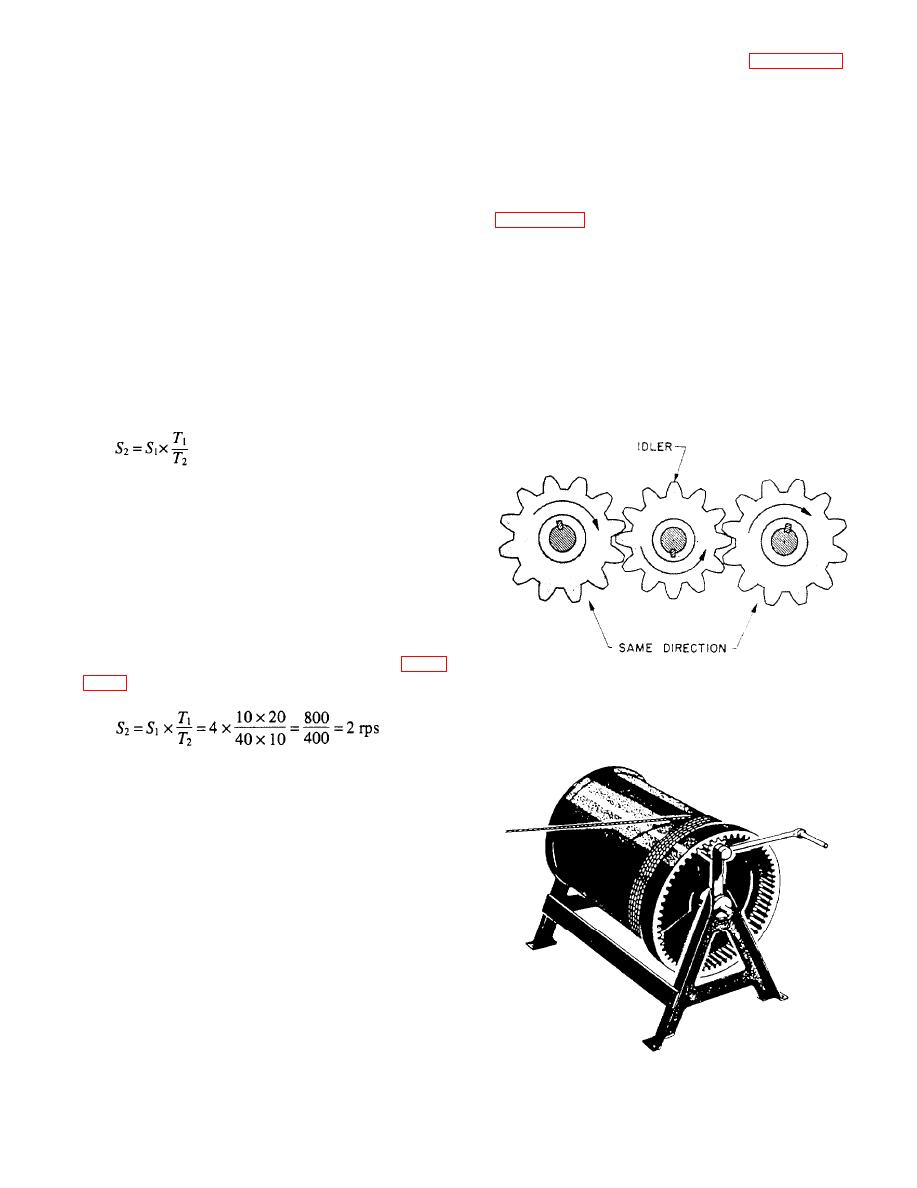

driven gear turn in the same direction. Figure 10-23

which mesh with the 40 teeth on wheel B. Wheel A

shows you how this works.

will have to rotate four times to cause B to make one

revolution. Wheel C is rigidly fixed on the same shaft

with B. Thus, C makes the same number of

MAGNIFYING FORCE WITH GEARS

revolutions as B. However, C has 20 teeth and meshes

with wheel D, which has only 10 teeth. Hence, wheel

Gear trains are used to increase the M.A. In fact,

D turns twice as fast as wheel C. Now, if you turn A

wherever there is a speed reduction, the effect of the

at a speed of four revolutions per second, B will be

effort you apply is multiplied. Look at the cable winch

rotated at one revolution per second. Wheel C also

in figure 10-24. The crank arm is 30 inches long, and

moves at one revolution per second and causes D to

the drum on which the cable is wound has a 15-inch

turn at two revolutions per second. You get out two

radius. The small pinion gear has 10 teeth, which mesh

revolutions per second after having put in four

with the 60 teeth on the internal spur gear. You will

revolutions per second. Thus, the overall speed

find it easier to figure the M.A. of this machine if you

reduction is 2/4--or 1/2--which means that you got

think of it as two machines.

half the speed out of the last driven wheel that you put

First, figure out what the gear and pinion do for

into the first driven wheel.

you. The theoretical M.A. of any arrangement of two

You can solve any gear speed-reduction problem

with the following formula:

Where

S1 = speed of first shaft in train

S2 = speed of last shaft in train

T1 = product of teeth on all drivers

T2 = product of teeth on all driven gears

Now use the formula on the gear train of figure

Almost any increase or decrease in speed can be

obtained by choosing the correct gears for the job. For

example, the turbines on a ship have to turn at high

speeds--say 5800 rpm--if they are going to be

efficient. But the propellers, or screws, must turn

rather slowly--say 195 rpm--to push the ship ahead

with maximum efficiency. So, a set of reduction gears

is placed between the turbines and the propeller shaft.

When two external gears mesh, they rotate in

opposite directions. Often you will want to avoid this.

Put a third gear, called an idler, between the driver and

the driven gear. But do not let this extra gear confuse

you on speeds. Just neglect the idler entirely. It does

not change the gear ratio at all, and the formula still

applies. The idler merely makes the driver and its

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |