|

|||

|

Page Title:

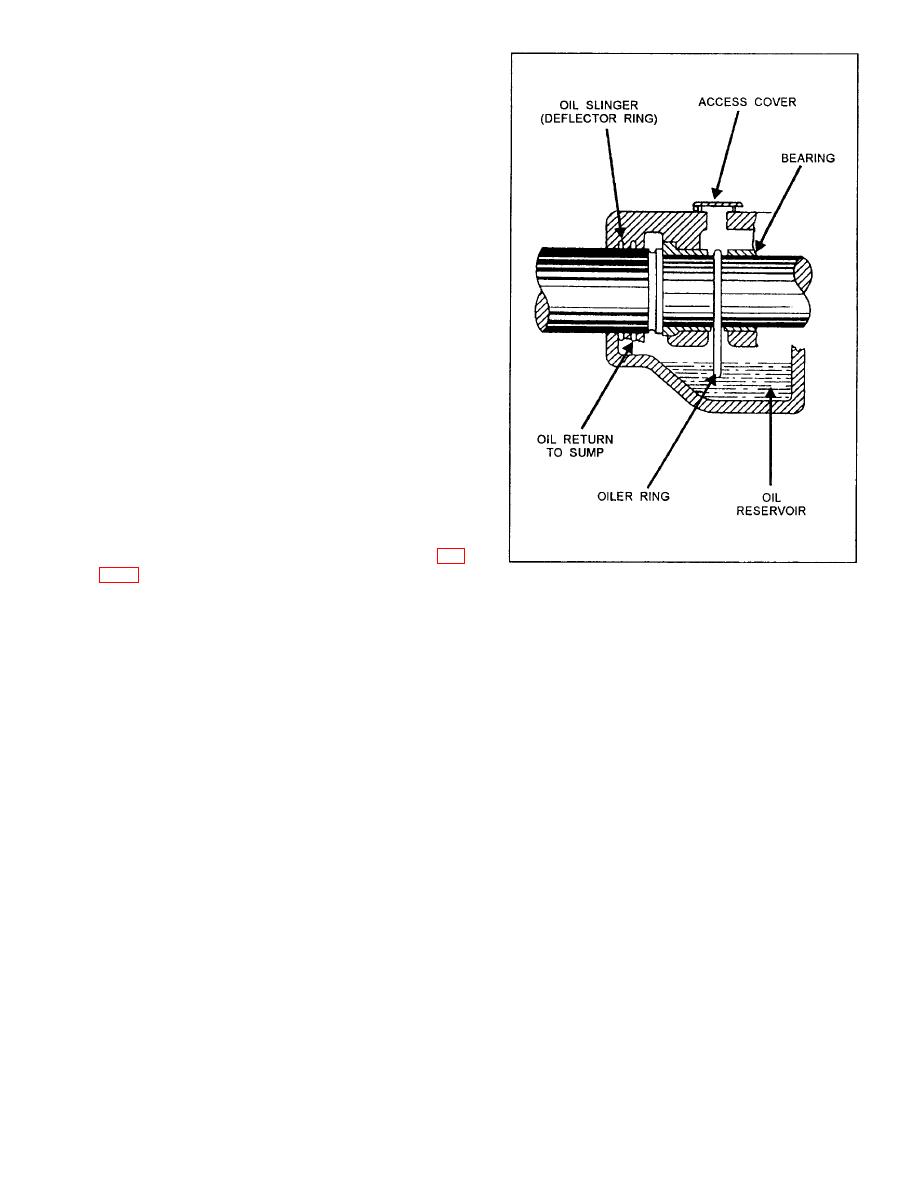

Figure 3-18.--Diagram of an oil-ring lubricated bearing. |

|

||

| ||||||||||

|

|

sleeve bearings requires periodic inspections of

bearing wear and lubrication.

motors, and large ship's service generators are

sometimes provided with a gauge for measuring

bearing wear. You can obtain bearing wear on a

sleeve-bearing machine not provided with a bearing

by measuring the air gap at each end of the machine

with a machinist's tapered feeler gauge. Use a blade

long enough to reach into the air gap without removing

the end brackets of the machine. Before making the

measurements, clean the varnish from a spot on a pole

or tooth of the rotor. A spot should also be cleaned at

the same relative position on each field pole of a dc

machine. For ac machines, clean at least three and

preferably four or more spots spaced at equal intervals

around the circumferences on the stator. Take the air

gap measurement between a cleaned spot on the rotor

and a cleaned spot on the stator, turning the rotor to

bring the cleaned spot of the rotor in alignment with

the cleaned spots on the stator. Compare these

r e a d i n g s with the tolerance stated by the

manufacturer's instruction book.

Oil Rings and Bearing Surfaces.-- An opening

is provided in the top of the bearing for you to check

the condition of the oil rings and bearing surfaces (fig.

certain that the oil ring is rotating freely when the

machine is running and is not sticking. With the

machine stopped, inspect the bearing surfaces for any

alarm contractors, which are incorporated in the ship's

signs of pitting or scoring.

alarm system. The contactor is preset to provide an

Trouble Analysis.-- The earliest indication of

alarm when the bearing temperature exceeds a value

sleeve bearing malfunction normally is an increase in

detrimental to bearing life. You should secure the

t h e operating temperature of the bearing.

affected machinery as soon as possible if a bearing

Thermometers are usually inserted in the lubricating

malfunction is indicated. A motor with overheated

oil discharge line from the bearing as a means of

sleeve bearings should be unloaded, if possible,

visually indicating the temperature of the oil as it

without stopping the motor. If you stop it immediately,

leaves the bearing. Thermometer readings are taken

the bearing may seize. The best way to limit bearing

hourly on running machinery by operating personnel.

damage is to keep the motor running at a light load and

However, a large number of bearing casualties have

supply plenty of cool, clean oil until the bearing cools

occurred in which no temperature rise was detected in

down.

thermometer readings; in some cases, discharge oil

Because the permissible operating temperature is

temperature has actually decreased. Therefore, after

often too high to be estimated by the sense of touch,

checking the temperature at the thermometer,

temperature measurements should be taken to

personnel should make a follow-up check by feeling

determine whether a bearing is overheated. A

the bearing housing whenever possible. Operating

thermometer securely fastened to the bearing cover or

personnel must thoroughly familiarize themselves

housing will usually give satisfactory bearing

with the normal operating temperature of each bearing

temperature measurements on machines not equipped

so they will be able to recognize any sudden or sharp

with bearing temperature measuring devices. Do not

changes in bearing oil temperature. Many large

insert a thermometer into a bearing housing, as it may

generators are provided with bearing temperature

3-24

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |