|

|||

|

|

|||

| ||||||||||

|

|

After removal, thoroughly clean the bearing. The

permanently lubricated bearings become inoperative,

replace them with bearings of the same kind. If not

recommended cleaner is standard solvent or clean oil.

already provided, attach DO NOT LUBRICATE

Soak the bearing in cleaner for as long as necessary to

nameplates to the bearing housing of machines with

dislodge dirt or caked grease from around the balls and

sealed bearings.

separators. After the bearing is cleaned, wipe it

carefully with a dry, lint-free cloth. If compressed air

Cleaning Ball Bearings

is used for drying, direct the airstream across the

bearing so that the bearing does not spin. Because a

You can clean an open or a single-sealed ball

dry bearing rusts quickly, protect the bearing at once

bearing only in an emergency when a suitable

by coating it with clean, low-viscosity lubricating oil.

replacement is not available. It is difficult to remove

Rotate the inner ring slowly by hand, and if the

dirt from ball bearings. Unless the cleaning is carefully

bearing feels rough, repeat the cleaning. After the

done, more dirt may get into the bearings than is

removed.

second cleaning, if the bearing still feels rough when

turned slowly by hand, renew it.

In cleaning an open, single-shielded or single-

sealed bearing, take the bearing off by applying a

For additional information on the cleaning and

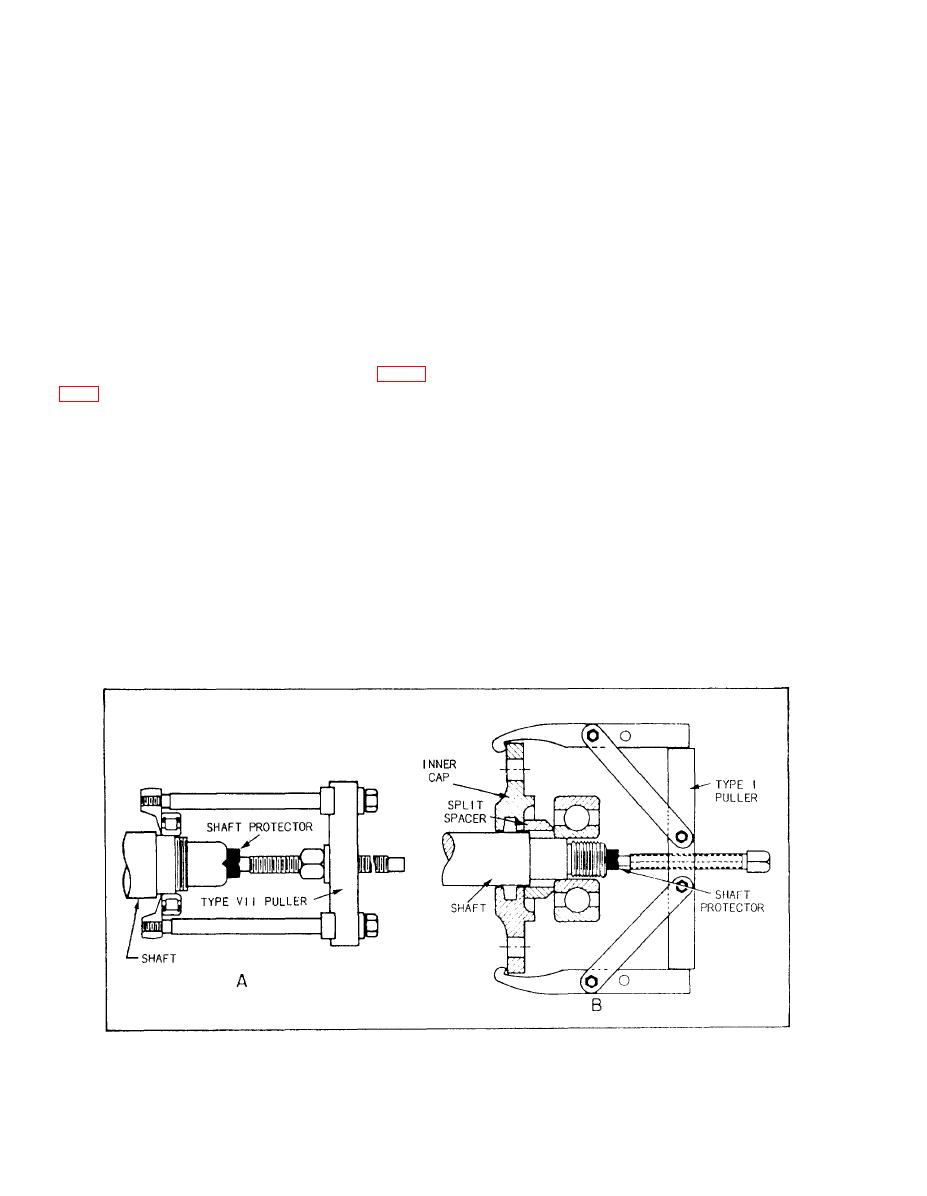

bearing puller to the inner race of the bearing. Figure

lubrication of ball bearings, refer to NSTM, chapter

244.

pullers, both of which apply the pulling pressure to the

inner race of the bearing. Removal of bearings by

of three types: right line (motion is parallel to the

pulling on the outer race tends to make the balls dent

elements of a sliding surface), journal (two machine

the raceway even when the puller is used. If bearings

parts rotate relative to each other), and thrust (any

are subjected to high temperatures, the race can be

force acting in the direction of the shaft axis is taken

distorted. This can cause the race to shrink to the shaft

up). Turbine-driven, ship's service generators and

more tightly. You should be careful not to damage the

propulsion generators and motors are equipped with

shaft when removing bearings. Use soft centers (shaft

journal bearings, commonly called sleeve bearings.

protectors), which are sometimes provided with a

The bearings may be made of bronze, babbitt, or

bearing removal kit. If not, the soft centers may be

made of soft metal. such as zinc or brass.

steel-backed babbitt. Preventive maintenance of

3-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |