|

|||

|

|

|||

| ||||||||||

|

|

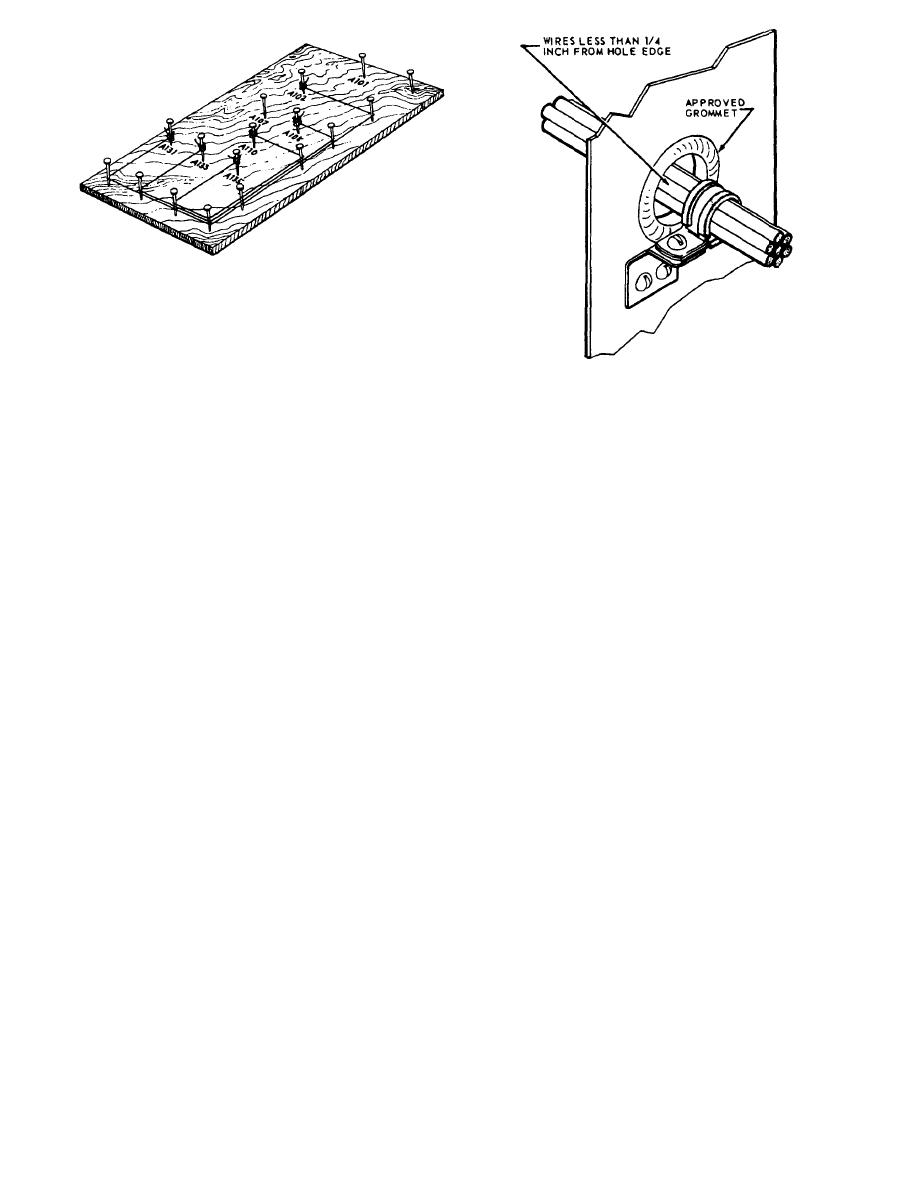

Figure 4-9.Harness form.

positions of the terminals on the board. Drive nails at

each terminal location and at points where the wires and

harness bend. Write the terminal designations near the

Figure 4-10.-Cable clamp and grommet.

appropriate nails, using the wiring diagram from the

equipment manual to double-check that terminal

markings are correct. When this is done, you can return

Wires passing through partitions or supports inside

the unit to service until it is convenient to install the new

a chassis must be supported at each hole by a cable

harness.

clamp or other permanent support. If the clearance

between the edge of the hole and the cable exterior is

The wires are run between the terminal points,

less than one-fourth of an inch, install a suitable

following the route outlined by the nails. Do not stretch

grommet in the hole (fig, 4-10).

the wires tight. The bitter ends of each wire are wrapped

around the nails located at its terminal positions. When

all terminals have been connected, the harness is formed

PREVENTIVE MAINTENANCE

and can be laced. If terminal connectors are to be used,

they are soldered in place after lacing is complete, and

The best maintenance is preventive, as potential

spaghetti put in place.

failures are detected and not given a chance to develop.

Preventive maintenance is defined as the measures

When the new harness is ready, you can install it in

taken periodically, or when needed, to achieve

a relatively short time. If it is to replace a harness in

maximum efficiency in performance, to ensure

equipment that is operating, the installation can be

continuity of service, and to lengthen the useful life of

postponed until the ship is in port or the unit is not

the equipment or system. This form of maintenance

needed.

consists principally of cleaning, lubrication, and

When installing or replacing wire or cable runs in

periodic inspections aimed at discovering conditions

equipment cabinets, make sure the slack between cable

that, if not corrected, may lead to malfunctions requiring

clamps is not excessive. Normally, wire should not sag

major repair.

by more than one-half of an inch when normal hand

pressure is applied. Allow enough slack at each end to

EQUIPMENT INSPECTIONS

prevent strain on the wire and to permit removal and

connection of plugs, replacement of terminal lugs, and

Equipment inspections fall into two main

free movement of shock and vibration-mounted

categories. First, there is the regular visual inspection of

equipment.

the mechanical aspects of the equipment. This

Bends in individual wires should not exceed a radius

inspection is conducted to find dirt, corrosion, loose

of 10 times the diameter of the wire or group of wires

connections, mechanical defects, and other sources of

except where the wire is suitably supported at each end

trouble. Second, there are functional inspections that are

of the bend; the minimum bend radius is 3 times the

accomplished by periodic testing and less frequent

diameter of the wire.

bench testing. To realize the most effective results from

4-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |