|

|||

|

Page Title:

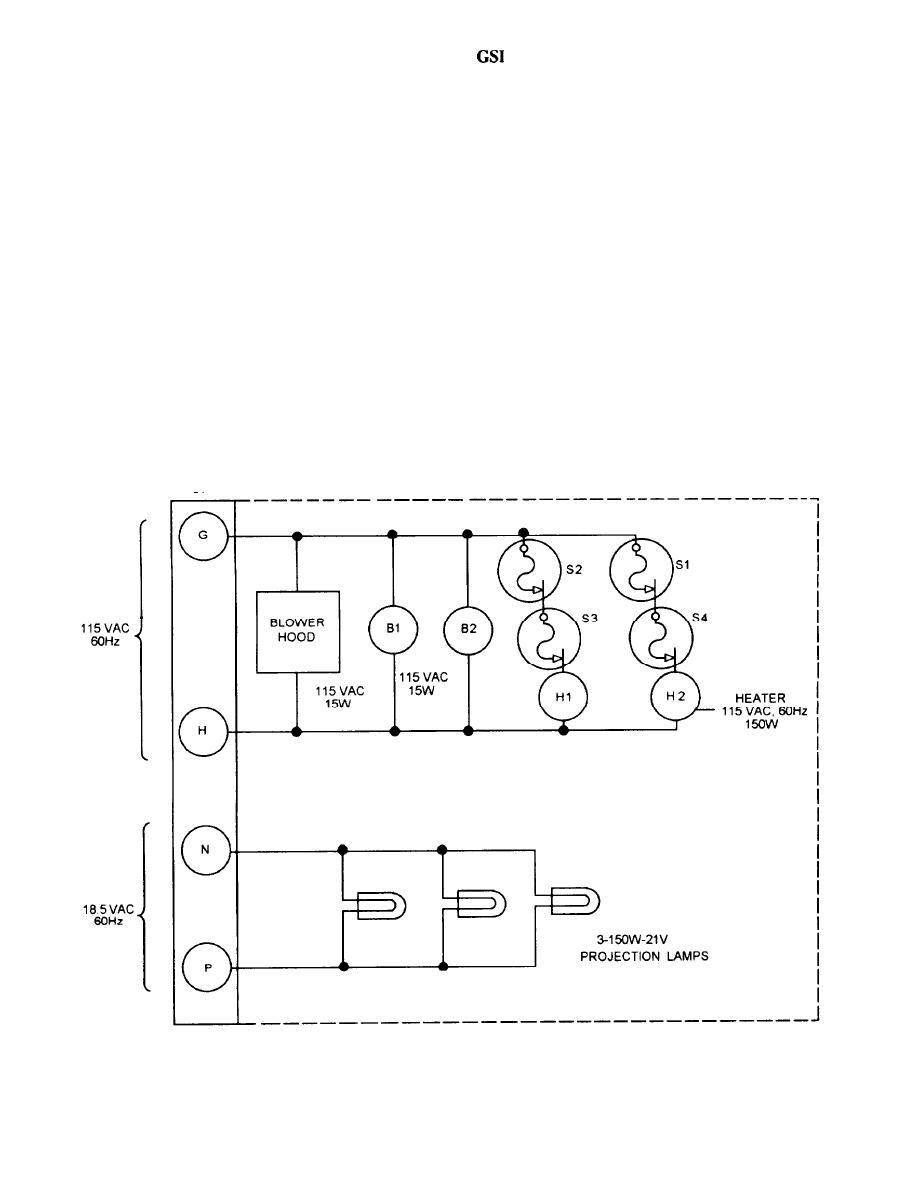

Figure 3-20.--GSI cell, simplified schematic. |

|

||

| ||||||||||

|

|

TRANSFORMER

temperature control is achieved by blowers, heaters, and

thermal switches.

The GSI uses three 21-volt 150-watt projection

The temperature control circuits (see figs. 3-20 and

lamps for its light source. This is about 21 amps of

current and would cause considerable voltage drop if

3-21) are used to regulate operating temperatures in the

long cables were used, thus the transformer assembly is

GSI assembly. When power is applied at the remote

mounted close to the GSI light and uses a fixed length

control panel, voltage is applied to the heaters and

of cable (10 feet) from the transformer secondary to

blowers to the left and right of the lens assemblies.

the GSI cell connector. The system autotransformer

Blower motors B1 and B2 begin to operate as soon as

supplying the primary voltage to the transformer is

located in the remote control panel. A simplified

voltage is applied. Control thermoswitches S1 and S2

schematic is shown in figure 3-21.

are set at 100 +10F. To keep this temperature constant,

S1 and S2 open and close as the temperature rises and

STABILIZED PLATFORM SYSTEM

falls in the GSI assembly. As the thermoswitches open

The stabilized platform system is an electro-

and close, power is removed from or applied to heaters

hydraulic served platform used to stabilize the GSI

H1 and H2. If S1 and S2 fail to open, backup thermo-

against the ship's pitch and roll. This keeps the tricolored

switches S3 and S4 will open, preventing damage to the

GSI light at a fixed angle to the horizon. The

lenses. A simplified schematic of the cell wiring appears

stabilization is termed a one-to-one stabilization system.

This means that for each degree of pitch or roll of the

in figure 3-20.

Figure 3-20.--GSI cell, simplified schematic.

3-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |