|

|||

|

Page Title:

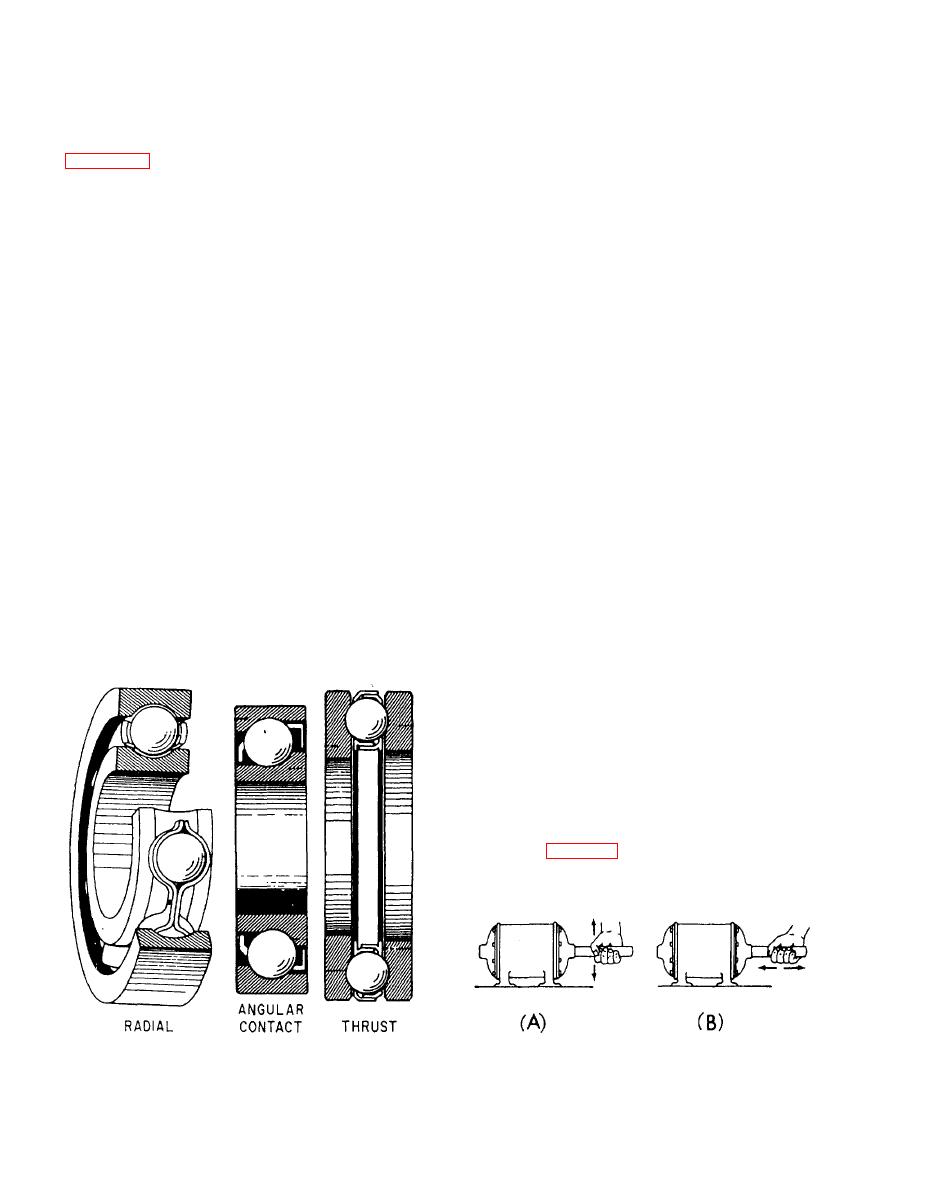

Figure 3-14.--Representative types of ball bearings. |

|

||

| ||||||||||

|

|

roller bearing used most extensively in the

by air-gap measurements would be more than enough

construction of electric motors and generators used in

to cause unsatisfactory operation of the machine.

the Navy. These bearings are further divided into three

The easiest way of determining the extent of wear

types dependent upon the load it is designed to

in these bearings is to periodically feel the bearing

bear--(1) radial, (2) angular contact, and (3) thrust.

housing while the machine is running to detect any

signs of overheating or excessive vibration, and to

The ball bearings on a rotating shaft of an electric

listen to the bearing for the presence of unusual noises.

motor or generator may be subjected to radial thrust

Rapid heating of a bearing may be an indication

and/or angular forces. While every ball bearing is not

o f danger. Bearing temperatures that feel

subjected to all three forces, any combination of one

uncomfortable to the touch could be a sign of

or more may be found depending on the equipment

dangerous overheating, but not necessarily. The

design. Radial loads are the result of forces applied to

bearing may be operating properly if it has taken an

the bearing perpendicular to the shaft; thrust loads are

hour or more to reach that temperature; whereas,

the result of forces applied to the bearing parallel to

serious trouble can be expected if high temperatures

the shaft; and angular loads are the result of a

are reached within the first 10 or 15 minutes of

combination of radial and thrust loads. The load

operation.

carried by the bearings in electric motors and

The test for excessive vibration relies to a great

generators is almost entirely due to the weight of the

extent on the experience of the person conducting the

rotating element. For this reason, the method of

test. The person should be thoroughly familiar with

mounting the unit is a major factor in the selection of

the normal vibration of the machines to be able to

the type of bearing installed when they are

correctly detect, identify, and interpret any unusual

constructed. In a vertically mounted unit, the thrust

vibrations. Vibration, like heat and sound, is easily

bearing is used, while the radial bearing is normally

telegraphed. A thorough search is generally required

used in most horizontal units.

to locate the source and determine its cause.

Wear of Bearings.-- Normally it is not necessary

Ball bearings are inherently more noisy in normal

to measure the air gap on machines with ball bearings

operation than sleeve bearings (discussed later). This

because the construction of the machines ensures

fact must be kept in mind by personnel testing for the

proper bearing alignment. Additionally, ball bearing

presence of abnormal bearing noise. A common

wear of sufficient magnitude as to be readily detected

method for sound testing is to place one end of a

screwdriver against the bearing housing and the other

end against the ear. If a loud, irregular grinding,

clicking, or scraping noise is heard, trouble is

indicated. As before, the degree of reliance in the

results of this test depends on the experience of the

person conducting the test.

Checking the movement of a motor or generator

shaft can also give an indication of the amount of

bearing wear. If the motor shaft has excessive vertical

movement (fig. 3-15, view A), it indicates worn

Vertical movement; (B) end-play movement.

3-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |