|

|||

|

Page Title:

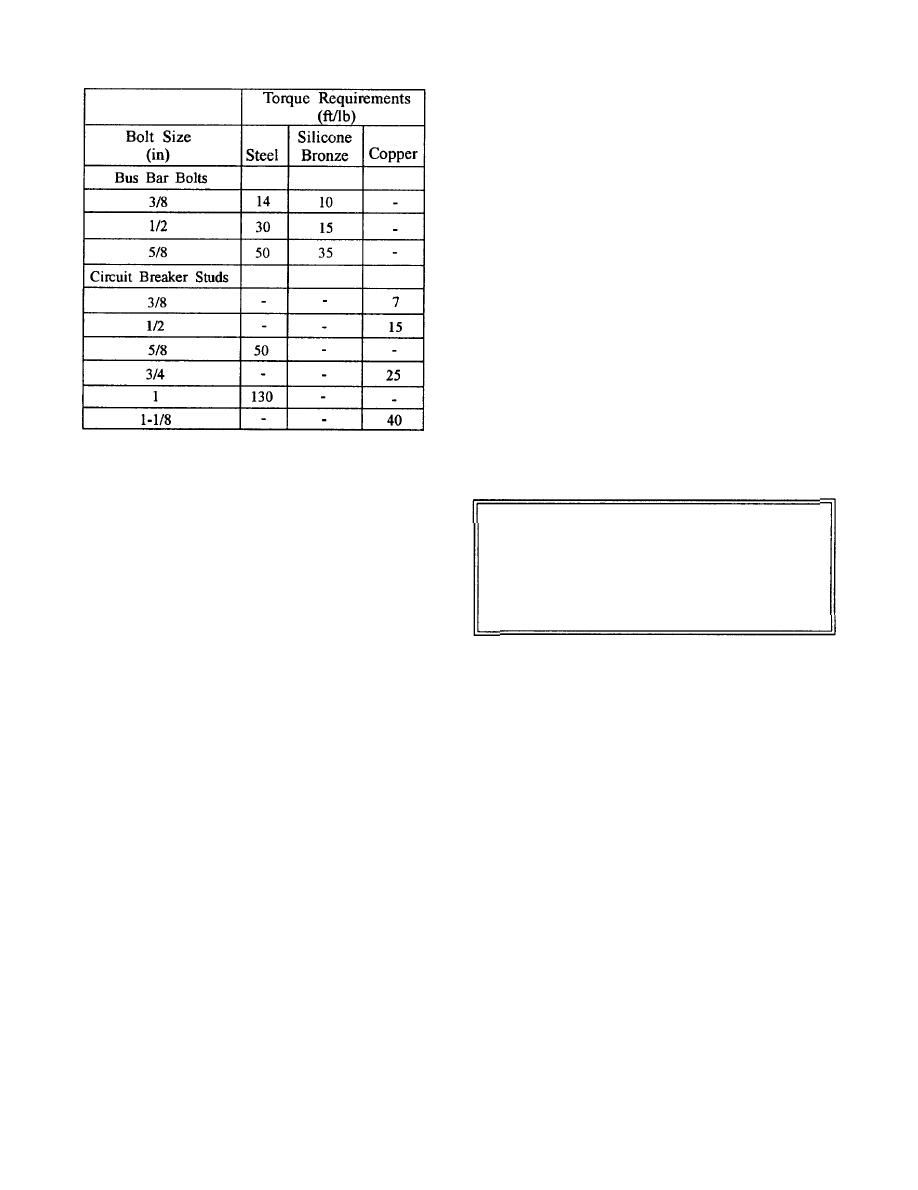

Table 3-1.--Common Bolt Size Torque Values |

|

||

| ||||||||||

|

|

Rheostats and Resistors

Be certain that ventilation of rheostats and

resistors is not obstructed. Replace broken or burned

out resistors. Temporary repairs of rheostats can be

made by bridging burned out sections when

replacements are not available. Apply a light coat of

petrolatum to the faceplate contacts of rheostats to

reduce friction and wear. Make sure that no petrolatum

is left in the spaces between the contact buttons as this

may cause burning and arcing. Check all electrical

connections for tightness, and wiring for frayed or

broken leads. Service commutators and brushes for

potentiometer-type rheostats according to instructions

for the dc machines.

Instruments

The pointer of each switchboard instrument

should read zero (except synchroscopes) when the

instrument is disconnected from the circuit. The

pointer may be brought to zero by external

screwdriver adjustment.

bus bars should be retaped as necessary according to

NSTM, chapter 320, "Electric Power Distribution

CAUTION

Systems," Check the condition of control wiring and

replace if necessary.

This should not be done unless proper

Bus bars and insulating materials can be cleaned

authorization is given.

with dry wiping cloths and a vacuum cleaner. Make

sure the switchboard or distribution panel is

completely de-energized and tagged out and remains

The pointer should not stick at any point along the scale.

Check instruments for accuracy whenever they have

so until the work is completed. Cleaning energized

been subjected to severe shock. Repairs to switchboard

parts should be avoided because of the danger to

instruments should be made only by the manufacturers,

personnel and equipment. Always observe electrical

shore repair activities, or tenders. For detailed

safety precautions when cleaning or working around

instructions on instruments, refer to NSTM, chapter 491,

switchboards.

"Electrical Measuring and Test Instruments."

Soap and water should not be used on the front

Fuses

panels of live front switchboards or on other panels of

insulating material. Use a dry cloth.

Make sure that fuses are the right size and that they

The front panels of dead front switchboards may

make firm contact with fuse clips. Ensure that lock-in

be cleaned without de-energizing the switchboard,

devices (if provided) are properly fitted and that all

fuse wiring connections are tight.

These panels can usually be cleaned by wiping with a

dry cloth. However, a damp, soapy cloth may be used

Control Circuits

to remove grease and fingerprints. Then, wipe the

surface with a cloth dampened in clear water to

Control circuits should be checked to ensure

remove all soap, and dry with a clean, dry cloth. The

circuit continuity and proper relay, contactor, and

cloths used in cleaning must be wrung out thoroughly

indication lamp operation. Because of the many types

so that no water is left to squeeze out and run down

of control circuits installed in naval ships, it is

impractical to list any definite operating test

the panel. Clean a small area at a time and wipe dry.

3-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |