|

|||

|

Page Title:

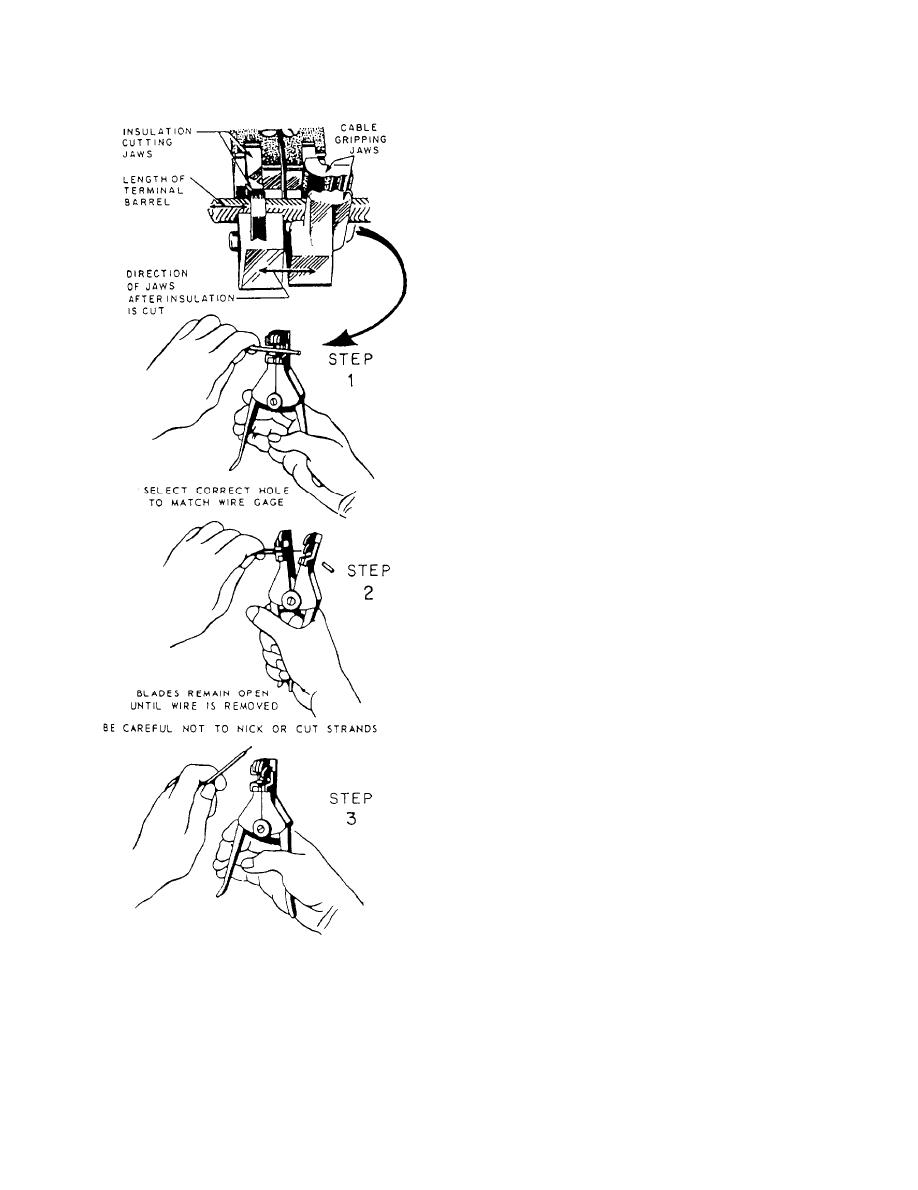

Figure 2-55.--Stripping wire with a hand stripper. |

|

||

| ||||||||||

|

|

a length equal to the length of the terminal barrel, clean

the individual strands thoroughly and twist them

tightly together. Solder them to form a neat, solid

terminal for fitting either approved clamp-type lugs or

solder-type terminals. If the solder-type terminal is

used, tin the terminal barrel and clamp it tightly over

the prepared conductor (before soldering) to provide

a solid mechanical joint. Conductor ends need not be

soldered for use with solderless-type terminals applied

with a crimping tool. Do not use a side, or diagonal,

cutter for crimping solderless-type terminals. Refer to

NEETS, module 4, for the proper procedures for

soldering and crimping.

Solderless-type terminals may be used for all

lighting, power, interior communications, and fire

control applications. However, equipment provided

with solder-type terminals by the manufacturer and

wiring boxes or equipment in which electrical

clearances would be reduced below minimum

standards require solder-type terminals.

For connection under a screwhead where a

standard terminal is not practicable, you can use an

alternate method. Bare the conductor for the required

distance and thoroughly clean the strands. Then twist

the strands tightly together, bend them around a

mandrel to form a suitable size loop (or hook where

the screw is not removable), and dip the prepared end

into solder. Remove the end, shake off the excess

solder, and allow it to cool before connecting it.

After the wiring installation has been completed,

measure the insulation resistance of the wiring circuit

with a Megger or similar (0 to 100 megohm, 500 volts

dc) insulation resistance measuring instrument. Do

not energize a newly installed, repaired, or modified

wiring circuit without first ascertaining (by insulation

tests) that the circuit is free of short circuits and

grounds.

Lacing Conductors

Conductors within equipment must be kept in

place to present a neat appearance and to facilitate

tracing of the conductors when alterations or repairs

are required. When conductors are properly laced,

they support each other and form a neat, single cable.

Use a narrow flat tape wherever possible for lacing

and tying. This tape is not an adhesive type of tape.

Round cord may also be used, but its use is not

preferred because cord has a tendency to cut into wire

insulation. Use cotton, linen, nylon, or glass fiber cord

or tape, according to the temperature requirements.

2-49

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |