|

|||

|

Page Title:

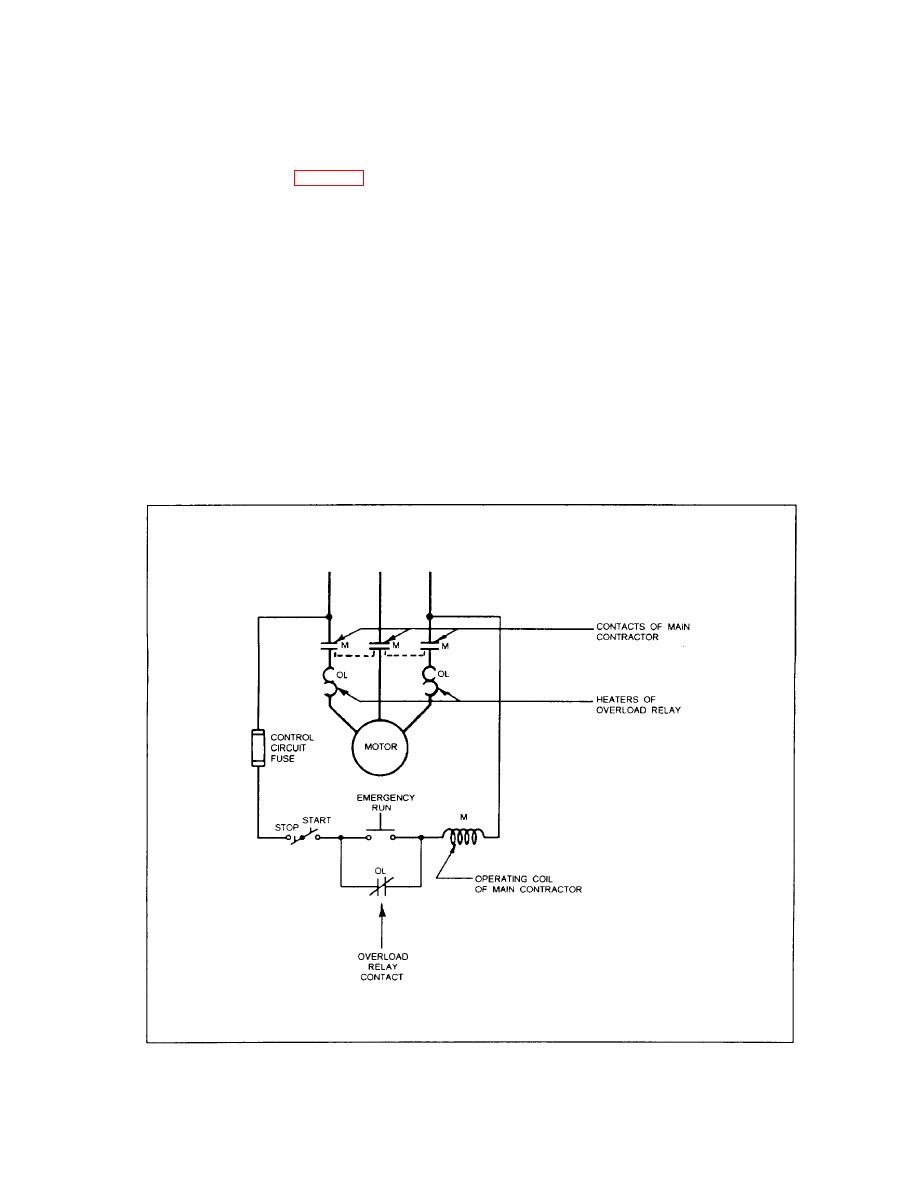

Figure 2-40.-Schematic diagram of motor controller with thermal type of overload relay. |

|

||

| ||||||||||

|

|

the relay. After the relay trips, the solder cools and

mechanism releases. The heater coils are rated so that

solidifies, and the relay is ready to be reset.

normal circuit current will not produce enough heat to

release the ratchet mechanism.

BIMETAL TYPE.-- The heat-sensitive element

is a strip or coil of two different metals fused together

The thermal type of overload relay has a heat-

along one side. When heated, one metal expands more

sensitive element and an overload heater connected in

than the other, causing the strip or coil to bend or

series with the motor circuit (fig. 2-40). When the

deflect and open the overload relay contacts.

motor current is excessive, heat from the heater causes

SINGLE-METAL TYPE.-- The heat-sensitive

the heat-sensitive element to open the overload relay

element is a metal tube around the heater. The tube

contacts. As it takes time for the heat-sensitive

lengthens when heated and opens the overload relay

element to heat up, the thermal type of overload relay

contacts.

has an inherent time delay. Thermal overload relays

INDUCTION TYPE.-- The heat-sensitive

may be of the solder-pot, bimetal, single-metal, or

element is usually a bimetal strip or coil. The heater

induction type.

consists of a coil in the motor circuit and a copper tube

SOLDER-POT TYPE.-- The heat-sensitive

inside the coil. The copper tube acts as a short-

element is a solder pot that consists of a cylinder inside

circuited secondary of a transformer and is heated by

a hollow tube. These are normally held together by a

the current induced in it. This type of overload relay

film of solder. In case of excessive motor current, the

is used only in ac controllers, whereas the previously

described types of thermal overload relays may be

heater melts the solder, breaks the bond between the

used in ac or dc controllers.

tube and cylinder, and releases the tripping device of

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |