|

|||

|

|

|||

| ||||||||||

|

|

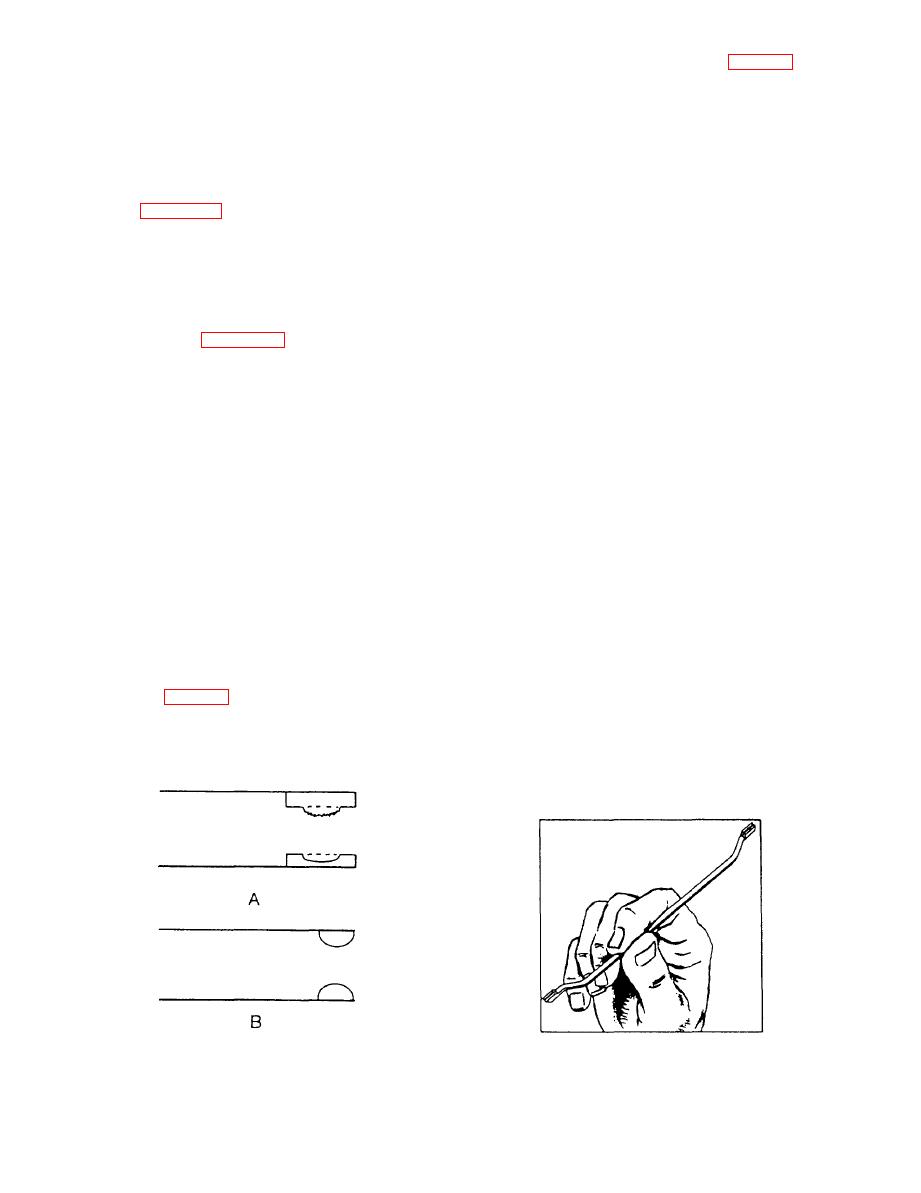

surfaces; and as the carbon rings build up, the relay

Relays similar to the shunt relay (fig. 2-24) have

contacts are held open.

replaceable contacts that should be maintained similar

to switch contacts. See Maintenance of Switches at the

When current flows in one direction through a

beginning of this chapter for further information.

relay, the contacts may be subjected to an effect called

During preventive maintenance you should check

cone and crater. The crater is formed by the transfer

for charred or burned insulation on the relay and for

of the metal of one contact to the other contact, the

darkened or charred terminal leads. Both of these

deposit being in the form of a cone. This condition is

conditions indicate overheating, and further

shown in figure 2-26, view A.

investigation should be made to determine the cause.

Some relays are equipped with ball-shaped

One possible cause for overheating is loose power

contacts which, in many applications, are superior to

terminal connections, allowing arcing at the

the flat contacts. Dust or other substances do not

connection.

collect as readily on a curved surface. In addition, a

Covers should not be removed from semisealed

ball-shaped contact can penetrate film more easily

relays in the field. Removal of a cover in the field,

than a flat contact. Figure 2-26, view B, shows a set of

although it might give useful information to a trained

ball-shaped contacts.

eye, may result in entry of dust or other foreign

When you clean or service ball-shaped relay

material that may cause poor contact or an open

contacts, be careful to avoid flattening or otherwise

circuit. Removal of the cover may also result in loss

altering the rounded surfaces of the contacts. A

of or damage to the cover gasket. When the relay is

burnishing tool should be used to clean relay contacts.

installed in a position where there is a possibility of

Be sure you do not touch the surface of the tool that is

contact with explosive fumes, extra care should be

used to clean the relay contacts. After the burnishing

taken with the cover gasket. Any damage to, or

tool is used, clean it with alcohol. Never use sandpaper

incorrect seating of, the gasket increases the

or emery cloth to clean relay contacts. Many relays

possibility of igniting the vapors.

have been damaged or ruined because the contact

Should an inspection determine that a relay has

points were cleaned with sandpaper or emery cloth

exceeded its safe life, the relay should be removed

instead of a burnishing tool. The use of sandpaper or

immediately and replaced with another of the same

emery cloth may cause bending of the contact springs

type. The replacement relay must have the same

and other damage. Excessively burned and pitted

characteristics or ratings, such as voltage, amperage,

contacts cannot be repaired by burnishing.

type of service, number of contacts, or continuous or

When a relay has bent contacts, you should use a

intermittent duty.

point bender (fig. 2-27) to straighten the contacts. The

Relay coils usually consist of a single coil. If a

use of any other tool could cause further damage, and

relay fails to operate, the coil should be tested for open

the entire relay would then have to be replaced.

circuit, short circuit, or short to ground. An open coil

is a common cause of relay failure.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |