|

|||

|

|

|||

| ||||||||||

|

|

rates. A heater is mounted around, or close to, the

of the contacts can be observed and the relays are

element, with the contacts mounted on the element

easily available for maintenance. Relays B, C, and F

itself. As the heat causes the element to bend (because

are semisealed relays. The covers provide protection

of the different thermal expansion rates), the contacts

from dust, moisture, and other foreign material, but

close to operate a relay. The delay time of the

can be removed for maintenance. Relays A and D are

bimetallic strips is usually from 1/2 to 1 1/2 minutes

examples of hermetically sealed relays. These relays

are protected from temperature or humidity changes

and is varied by using metals with different expansion

rates or by increasing or decreasing the distance

as well as dust and other foreign material. The covers

between the fixed and moving contacts.

cannot be removed, thus making the relay tamper-

proof.

One common form of time delay relay uses a lag

coil, which is usually a large copper slug located at

Clapper Relay

one end of the winding or a tubular sleeve located

between the winding and the core. The lag coil (slug)

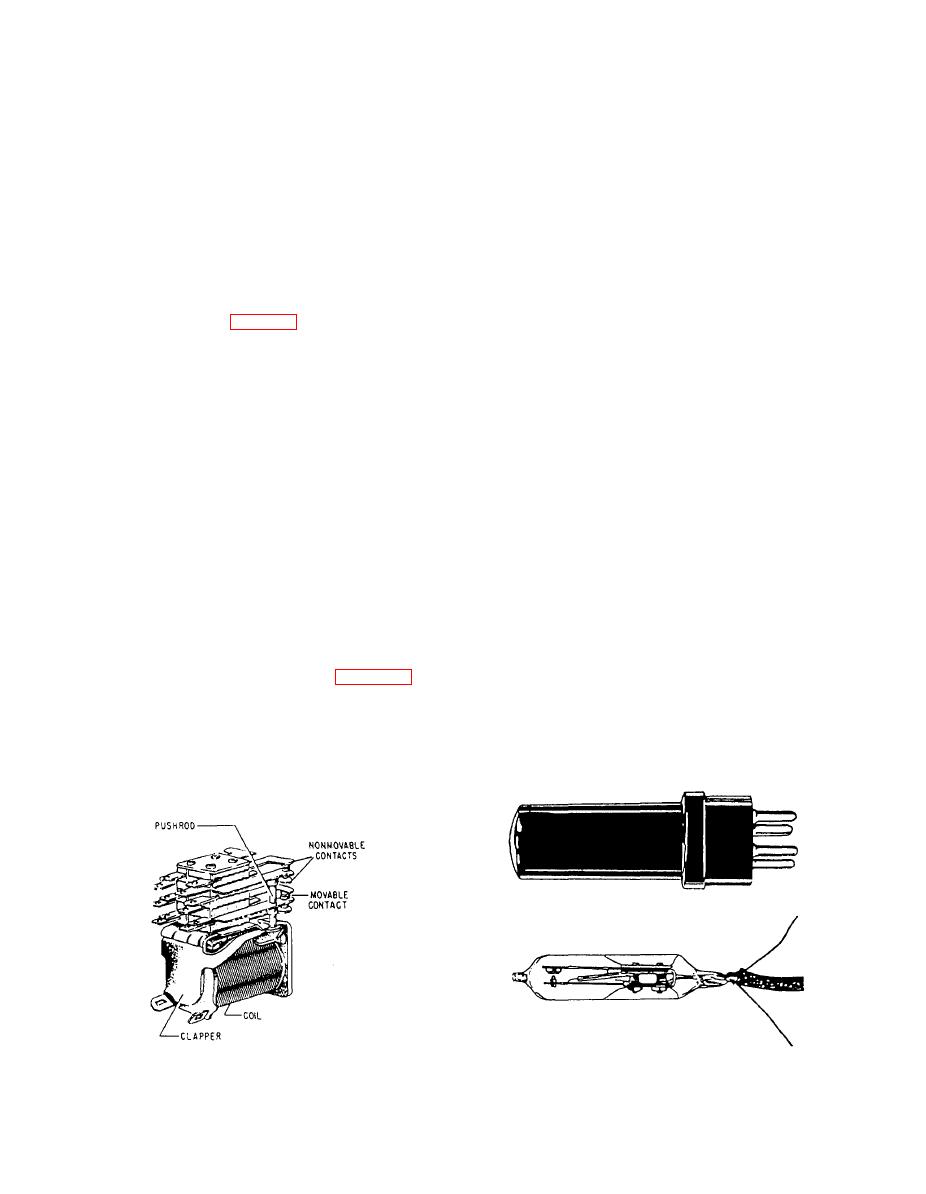

The clapper relay (fig. 2-22) has multiple sets of

acts as a short-circuited secondary for the relay coil.

contacts. As the circuit is energized, the clapper is

The counter magnetomotive force (mmf), due to the

pulled to the magnetic coil. Pulling the arm of the

current induced in the coil by the changing coil

clapper forces the movable contact upward to move

current, delays the flux buildup or decay in the air gap

the pushrod and the upper movable contact. This

and hence the closing or opening of the armature. A

action could be repeated for as many sets of contacts

short slug near the armature end of the core has

as required. Thus, it is possible to control many

relatively more effect on the operating time, and one

different circuits simultaneously. To the maintenance

at the heel end has more effect on the release time.

person, this type of relay can be a source of trouble.

The motion of the clapper arm does not necessarily

Latch-In Relay

assure the tandem movement of all the movable

contacts. If the pushrod was broken, the clapper arm

Another type of relay is the latch-in relay. This

would push the lower movable contact upward but

relay is designed to lock the contacts in the

would not move the upper moveable contact, thereby

de-energized position until the relay is either

not completing the circuit.

manually or electrically reset. Two windings are used:

the trip coil and the reset coil. When the trip coil is

Thermal Time Delay Relay

energized, it acts on a spring-loaded armature. The

movable contacts of the relay are mounted on this

A thermal time delay relay (fig. 2-23) is

armature. After the contacts open they are held in the

constructed to produce a delayed action when

open position by a mechanical latch. The mechanical

energized. Its operation depends on a thermal action,

latch is unlatched when the reset coil is energized,

such as that of a bimetallic element being heated. The

thus allowing the relay's contact to close again.

element is made by welding together two strips of

different metals having different thermal expansion

2-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |