|

|||

|

Page Title:

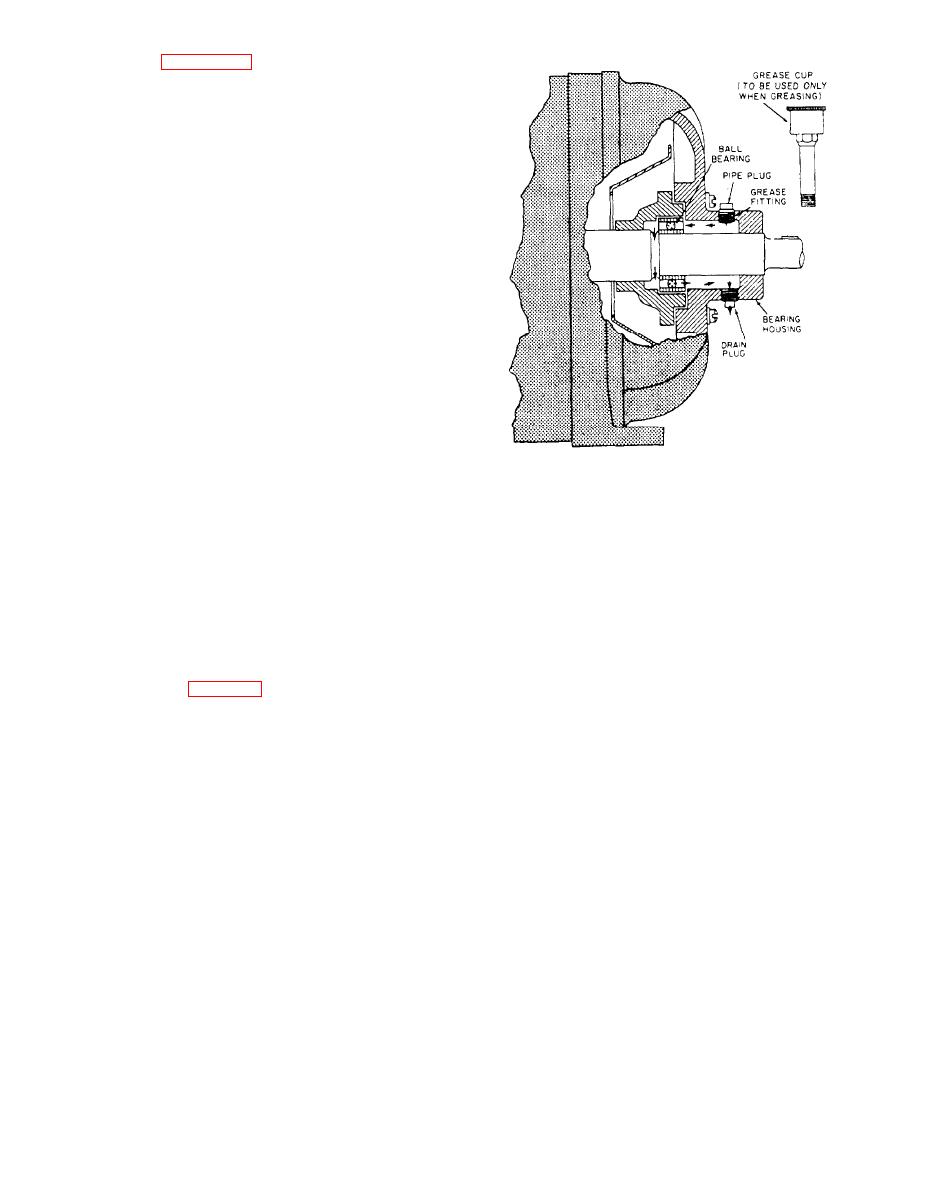

Figure 3-16.--Grease-lubricated ball bearings. |

|

||

| ||||||||||

|

|

bearings. Figure 3-15, view B, shows how to get a

rough approximation of motor or generator end-play

movement. You can correct excessive end-play, as

described in the applicable technical manual, by

adding bearing shims.

Lubrication

One cause of motor and generator failure is

overlubrication. Forcing too much grease into the

bearing housing seals and onto the stationary windings

and rotating parts of the machine will cause

overheating and deterioration of insulation, eventually

resulting in electrical grounds and shorts. Overheating

will also cause rapid deterioration of the grease and

the eventual destruction of a bearing. To avoid

overlubrication, add new lubricant only when

necessary.

The frequency that new grease must be added

depends on the service of the machine and the

tightness of the housing seals, and the requirements

should be determined for each machine by the

engineer officer or PMS requirements. A large

One common method by which the oil level is

quantity of grease coming through the shaft extension

maintained in ball bearings is the wick-fed method. In

end of the housing usually indicates excessive leakage

this method, the oil is fed from an oil cup to the inside

inside the machine.

of the bearing housing through an absorbent wick.

To prevent greasing by unauthorized personnel,

This wick also filters the oil and prevents leakage

remove the grease cups from motors and generators.

through the cup if momentary pressure is built up

Insert pipe plugs in place of the grease cups. Replace

within the housing.

the pipe plugs temporarily with grease cups during

Grease-Lubricated Ball Bearings.-- Preferred

lubrication (fig. 3-16). (Removable grease cups

Navy bearing greases for shipboard auxiliary

should remain in the custody of the responsible

machinery are as follows:

maintenance personnel.) Make sure the grease cups

1. Bearings operating below 110C (230F) in

are clean. After the grease is added, clean the pipe

plugs before replacing them.

non-noise or noise-critical application should use

DOD-G-24508 grease. It is available in a 1-pound can.

The preferred method of adding grease calls for

2. Bearings operating near water (for example,

disassembly of the bearing housing. Although not

rudder stock bearings) should use MIL-G-24139

recommended, renewing the bearing grease without at

grease. It is available in a 5-pound can.

least partially disassembling the housing may be tried

under certain conditions.

DOUBLE-SHIELDED OR DOUBLE-SEALED

BALL BEARINGS SHOULD NEVER BE DIS-

Oil-Lubricated Ball Bearings.-- Lubrication

ASSEMBLED OR CLEANED. These bearings are

charts or special instructions are generally furnished

prelubricated. Cleaning will remove the lubricant

for electric motors and generators equipped with

from the bearings or can dilute the lubricant until it no

oil-lubricated ball bearings. The oil level inside the

longer possesses its original lubricating qualities.

bearing housing should be maintained about even with

the lowest point of the bearing inner ring. At this level,

Permanently lubricated ball bearings require no

there will be enough oil to lubricate the bearing for its

greasing. You can recognize equipment furnished

with these bearings by the absence of grease fittings

operating period, but not enough to cause churning or

or the provision for attaching grease fittings. When

overheating.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |