|

|||

|

Page Title:

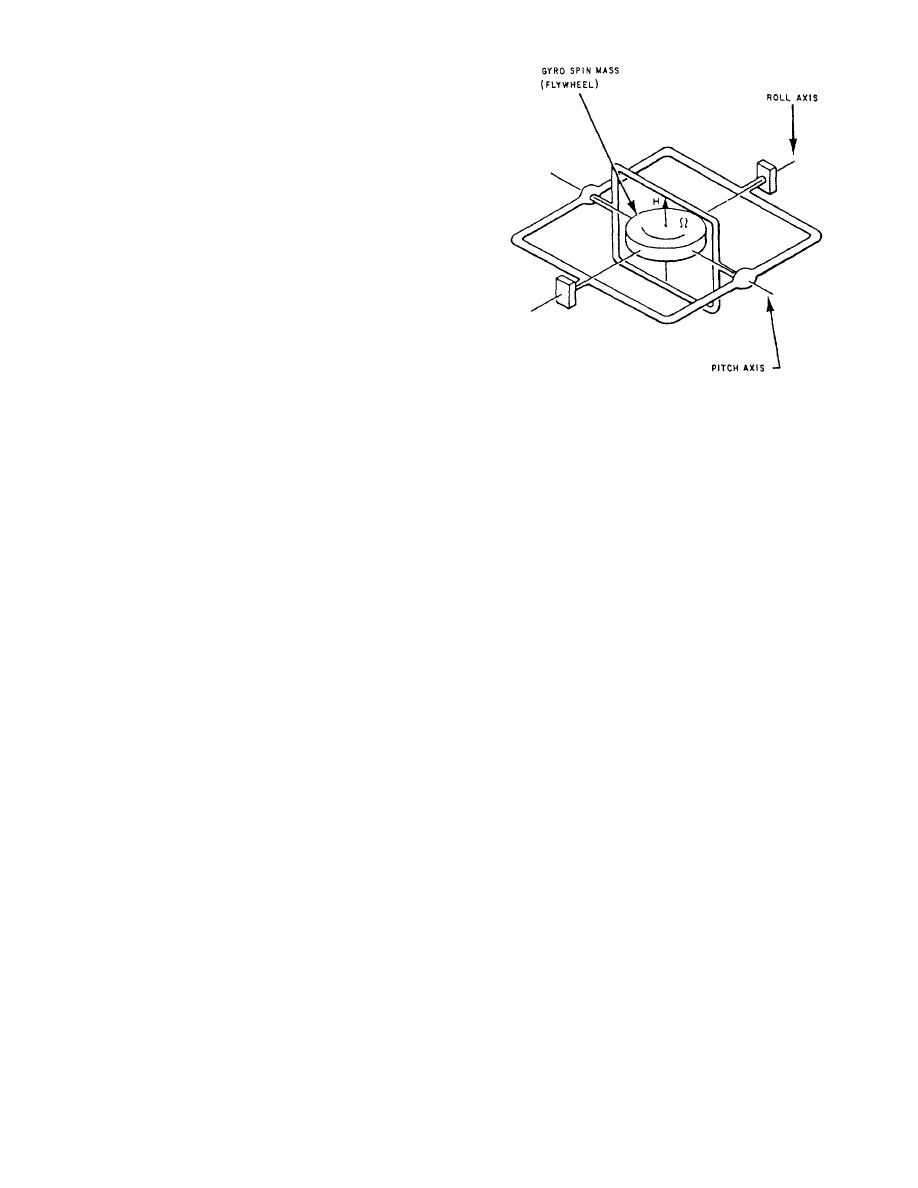

Figure 3-14.--Vertical gyro, simplified schematic. |

|

||

| ||||||||||

|

|

you can locate the cause of the specific malfunction and

perform the recommended corrective maintenance.

Maintenance is an ongoing process to keep the

equipment operating effciently and consists of pre-

ventive and corrective maintenance. For all main-

tenance requirements for the SGSI system, you should

refer to the maintenance requirement cards (MRCs).

There are maintenance items to be performed weekly,

quarterly, semiannually, and annually. System main-

tenance must be performed on a regular basis regardless

of use cycle. Deterioration and/or damage to equipment

may result if system maintenance is not performed

regularly. The information given in the following para-

graphs is not intended to replace preventive main-

tenance cards or the applicable technical manuals. This

information should familiarize you with some of the

requirements and procedures to keep the equipment in

Figure 3-14.--Vertical gyro, simplified schematic.

top notch operating condition.

GYRO ALARM OFF

When the flywheel of the gyroscope is rotating at

high speed, its inertia is greatly increased. This causes

If a failure occurs in the error sensing circuitry or if

the flywheel to remain stationary within the gyro gimbal

the ship's gyro information or gyro reference voltage is

structure. To align the gyroscope flywheel to the local

not being sent to the SGSI, a ready light cannot be

earth gravity vector (downward pull of gravity), a

obtained. This will keep the lamp relay de-energized and

pendulum sensor is attached under the spinning fly-

not allow the source lamps to illuminate. Operation in

wheel. In operation, the pendulum is held suspended

the internal gyro mode is still possible through the

within a magnetic sensor with the magnetic sensor

activation of the gyro alarm off switch-indicator on the

measuring the difference between the pendulum axis

component panel assembly. Since the gyro alarm off

and the spin motor axis. The sensor output is amplified

switch-indicator disables the independent failure detec-

tion circuit, a gyro alarm off indicator is automatically

flywheel to rotate in a direction to reduce the sensor

illuminated in both the electronic enclosure and the

output. In actual operation, the pendulum sensor is

remote control panel. Servo error sensing is not affected

affected by lateral accelerations that cause it to oscillate

by activation of gyro alarm off. Depressing the gyro

about true position. To correct for this oscillation, the

alarm off push button will activate the ready light and

gyro circuits time constants are long. The long time

allow the source lamps to illuminate if no other system

constants cause the gyros flywheel to ignore periodic

problems exist.

variations of the pendulum and align itself to the average

pendulum position. Figure 3-15 shows the essential

GYRO FAILURE ALARM CIRCUIT TESTS

elements of the gyro.

These tests are to be performed once a week when

CELL ALIGNMENT

the SGSI is being used for air operations. These tests

will ensure that all failure monitoring circuits are

For a pilot to use the SGSI for an accurate landing,

operational.

the cell must be properly aligned. There are two adjust-

ments necessary for this alignment. One adjustment is

VERTICAL GYROSCOPE

focusing the cell and the other is setting the beam angle

in reference to the GSI base plate.

The vertical gyroscope is basically a mechanical

device. The essential element of the gyroscope is a

Cell Focusing

flywheel rotating at high angular velocity about an axis.

The flywheel is mounted within gimbals that allow it

As shown in the simplified cell schematic, fig-

ure 3-16, you can see that by moving the light mask into

two degrees of freedom as shown in figure 3-14.

3-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |