|

|||

|

Page Title:

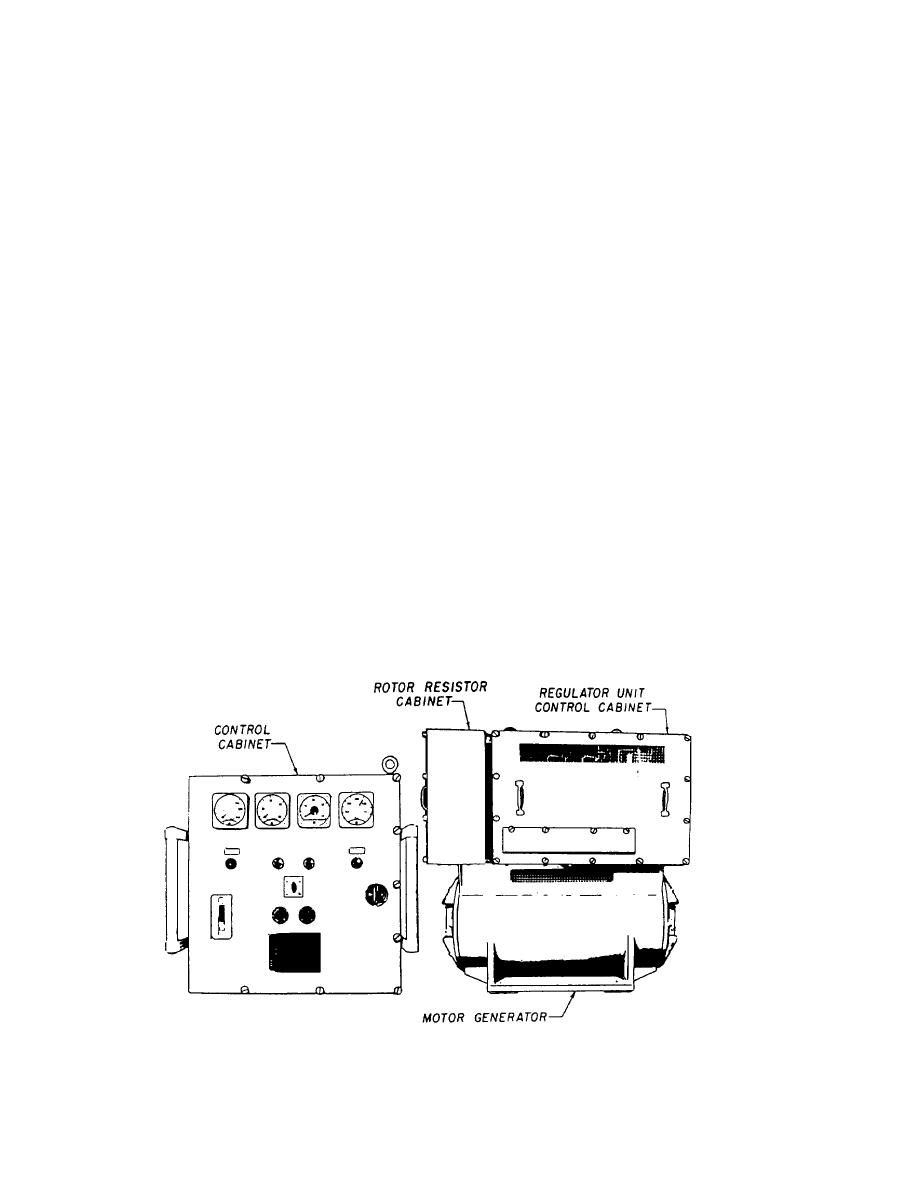

Figure 1-25.-Motor generator set with control equipment. |

|

||

| ||||||||||

|

|

double row width, and a "Warning Do Not Lubricate

FREQUENCY REGULATORS

Bearings" instruction plate is mounted on the unit.

Frequency regulators are used to provide a regulated

frequency for frequency-sensitive equipment. To

MOTOR GENERATOR

troubleshoot frequency regulators, you need to have an

understanding of motor generators, as frequency and

voltage regulators are part of the control circuits for

In a 30-kW motor generator, since a constant speed

motor generators. The following paragraphs will discuss

is required for a constant frequency, the change in motor

motor generators and the troubleshooting of frequency

rotor current for changes in torque requirement is

regulators. Detailed troubleshooting charts for

accomplished through the external means of varying the

frequency regulators can be found in the service manual

tiring angle of three silicon controlled rectifiers (SCRs).

Motor Generator Set 30 KW, 440.450 V AC, 60/400

The basic operation of an SCR is as follows. The

Cycle, 3 Phase with Control Equipment.

SCR has a positive-negative-positive-negative (PNPN)

device structure and is the semiconductor equivalent of

a gas thyratron. It is constructed by making both an

30 kW CLOSELY REGULATED MOTOR

alloyed PN junction and a separate ohmic contact to a

GENERATOR SET

diffused PNP silicon pellet. Schematic representation of

the SCR is shown in figure 1-26. With reverse voltage

The 30-kW 440/450-volts ac, 60/400-Hz, 3-phase

(encircled polarities) impressed on the device (cathode

motor generator set (fig. 1-25) consists of a wound rotor

positive), it blocks the flow of current as in an ordinary

induction motor driving a synchronous generator.

rectifier. With positive voltage applied to the anode

Internal control circuits include voltage and frequency

(uncircled polarities), the SCR blocks the flow of

regulating systems, a motor controller (magnetic

current until either the forward breakdown voltage is

starter), and generator output circuit breakers. The unit

reached, or a suitable gate pulse is applied to the gate.

is designed for parallel operation with an identical unit.

In practical application, the positive pulse applied to the

Its housing is dripproof.

gate is used to control the firing of the SCR. At this point,

The wound rotor motor and generator is a

the SCR switches to a high-conduction state; the current

flow is limited only by the external circuit impedance

two-bearing unit with motor and generator rotors, plus

and supply voltage. The magnitude of gate impulse

a self-cooling fan mounted on a single shaft. The single

needed to turn on an SCR varies with temperature and

row ball bearings are prelubricated, double sealed,

Figure 1-25.-Motor generator set with control equipment.

1-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |