|

|||

|

|

|||

| ||||||||||

|

|

operate in parallel without speed droop with changing

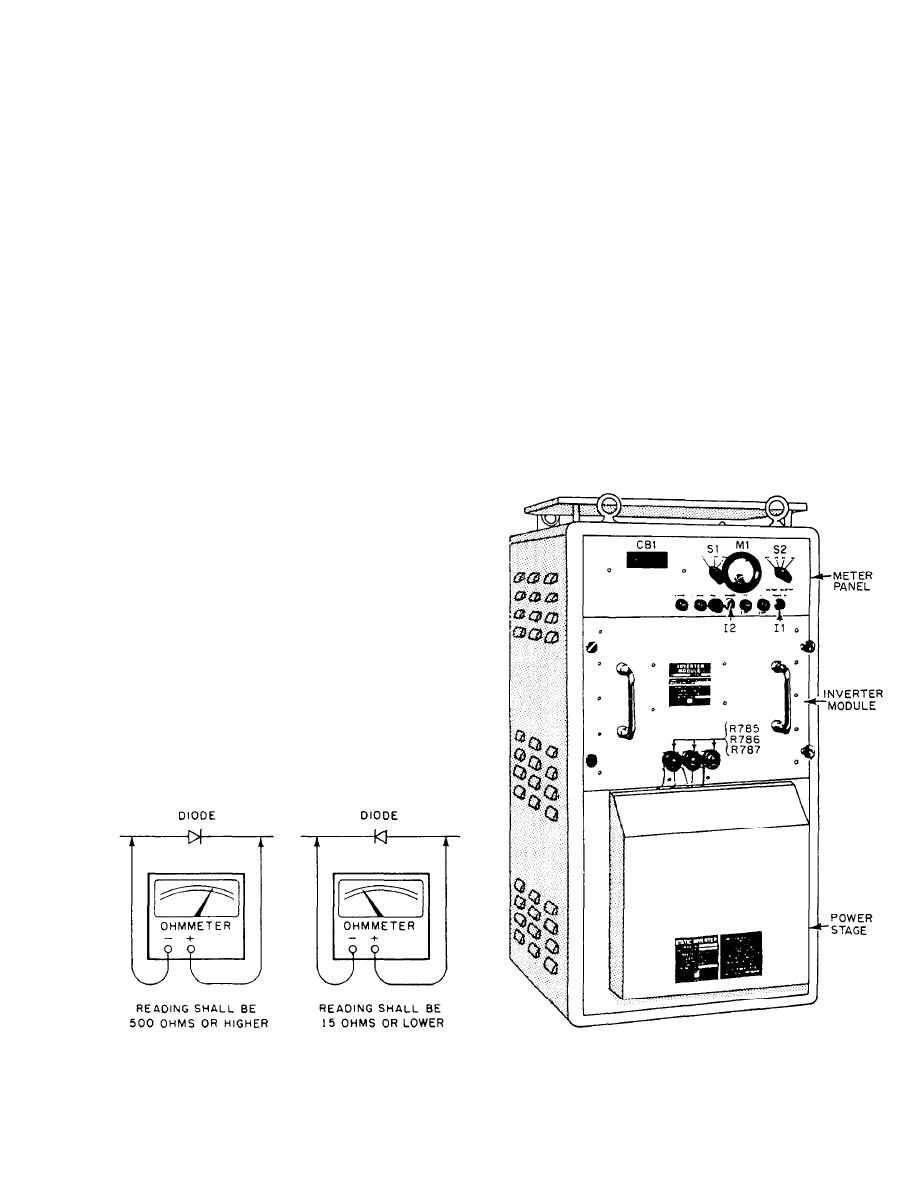

and the negative lead is connected to the cathode side,

load and to divide the load (kW) evenly between them.

the ohmmeter will indicate a low value (15 ohms or

less). With the ohmmeter leads reversed across the

SAFETY

diode, a higher reading will be obtained (Refer to

fig. 1-36) A front to back ratio of 10 to 1 is usually

The inherent dangers of rotating machinery are kept

considered a good diode.

to a minimum; however, it remains the responsibility of

Various test setups have been devised for transis-

supervisory personnel to ensure that personnel

tors, and often they are included in the manufacturer's

performing preventive and corrective maintenance are

technical manual.

thoroughly acquainted with the possible hazards

A key to good maintenance that should be stressed

involved. Except during supervised maintenance, all

is familiarity with the manufacturer's technical manual.

doors and covers should be in place. Since considerable

semiconductor application is made here, test equipment

settings and proper soldering techniques must be

STATIC INVERTER

observed when maintenance is required.

The need for a highly dependable, static, 400-Hz

MAINTENANCE

power supply led to the development of the 4345A static

inverter.

The 3-M system provides adequately for preventive

The model 4345A static inverter delivers a closely

maintenance on the motor generator. No corrective

regulated 400-Hz, 3-phase, 120-volt output from a

maintenance should be attempted without a thorough

250-volt dc source. Two single-phase static inverters are

understanding of the pertinent sections of the

manufacturer's technical manual. Troubleshooting

charts are of great value when employed with test

procedures in identification and isolation of problem

areas.

One test that may be of some assistance is that used

for silicon diodes. With this test, the silicon diodes may

be tested without removal from the circuit by the use of

a low-range (0-500 ohms) ohmmeter. The test is

performed by readings taken with the ohmmeter leads

connected across the diode in the opposite or reverse

direction. This means that the positive lead of the

and then to the opposite side. Comparison of the reading

will indicate the condition of the diode. When the

positive lead is connected to the anode side of the diode

Figure 1-36.-Diode test.

Figure 1-37.-Static inverter.

1-30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |