|

|||

|

Page Title:

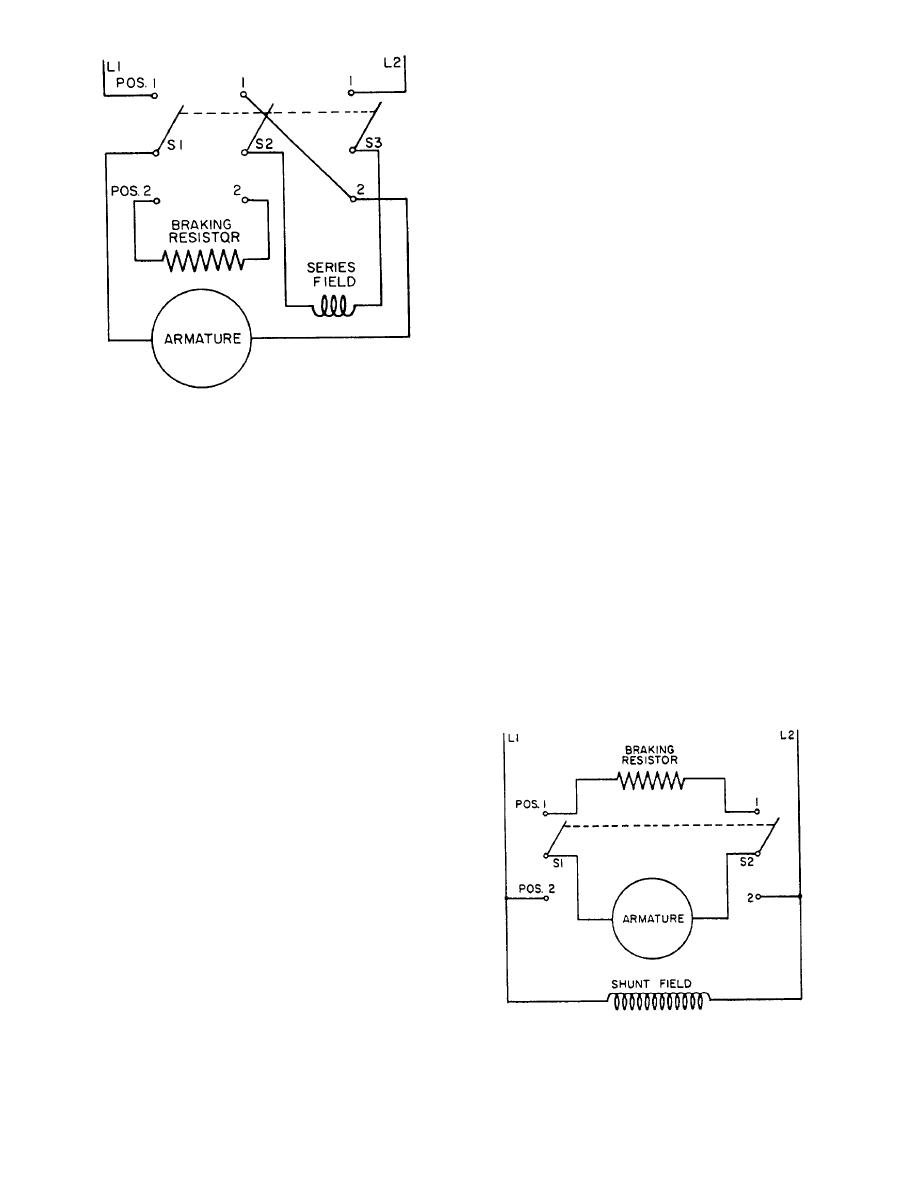

Figure 1-23.-Connections for dynamic braking of a shunt-wound dc motor. |

|

||

| ||||||||||

|

|

the switch arms are in position 1, the armature is dis-

connected from the line and connected to the resistor.

The shunt field remains connected to the line. As the

armature turns, it generates a countervoltage that forces

the current through the resistor. The remainder of the

action is the same as described for the circuit in fig-

ure 1-22.

Although dynamic braking provides an effective

means of slowing motors, it is not effective when the

field excitation fails or when an attempt is made to hold

heavy loads; without rotation, the countervoltage is

zero, and no braking reaction can exist between the

armature and the field.

Dc Magnetic Brake

Magnetic brakes are used for complete braking

protection. In the event of field excitation failure, they

Figure 1-22.-Connections for dynamic braking of a

will hold heavy loads. A spring applies the brakes, and

series-wound dc motor.

the electromagnet releases them.

Disk brakes are arranged for mounting directly to

from a controller. With the switch arms in position 1,

the motor end bell. The brake lining is riveted to a steel

the motor operates from the line. When the switch arms

disk, which is supported by a hub keyed to the motor

are in position 2, the resistor is connected in series with

shaft. The disk rotates with the motor shaft.

the field, and, at the same time, the field coil connection

The band-type brake has the friction material

to the armature is reversed. Thus, as long as the armature

fastened to a band of steel, which encircles the wheel or

turns, it generates a countervoltage, which forces cur-

drum and may cover as much as 90 percent of the wheel

rent through the resistor and the series field. Although

surface. Less braking pressure is required and there is

the direction of current flow through the armature is

less wear on the brake lining when the braking surface

reversed (because of the countervoltage), the direction

is large.

through the series field coil is not reversed. When

operating in this way, the motor is essentially a generator

The dc brakes are operated by a solenoid similar in

that is being driven by the momentum of the armature

design to the ac solenoid brake (fig. 1-20), except that

and the mechanical load. Energy is quickly consumed

in forcing current through the resistor, and the armature

stops turning.

The time required to stop the motor maybe varied

with different resistor values. The lower the resistance,

the faster the braking action. If two or more resistors are

connected by switches, the braking action can be varied

by switching in different load resistors. Usually, the

same braking resistors that are used to stop the motor

are also used to reduce the line voltage during

When dynamic braking is used with a dc shunt-

wound motor, resistance is connected across the

armature (fig. 1-23).

Switches S1 and S2 are part of a double-pole

double-throw (DPDT) circuit breaker assembly. When

Figure 1-23.-Connections for dynamic braking of a

the switch arms are connected to position 2, the armature

shunt-wound dc motor.

is across the line, and motor operation is obtained. When

1-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |