|

|||

|

Page Title:

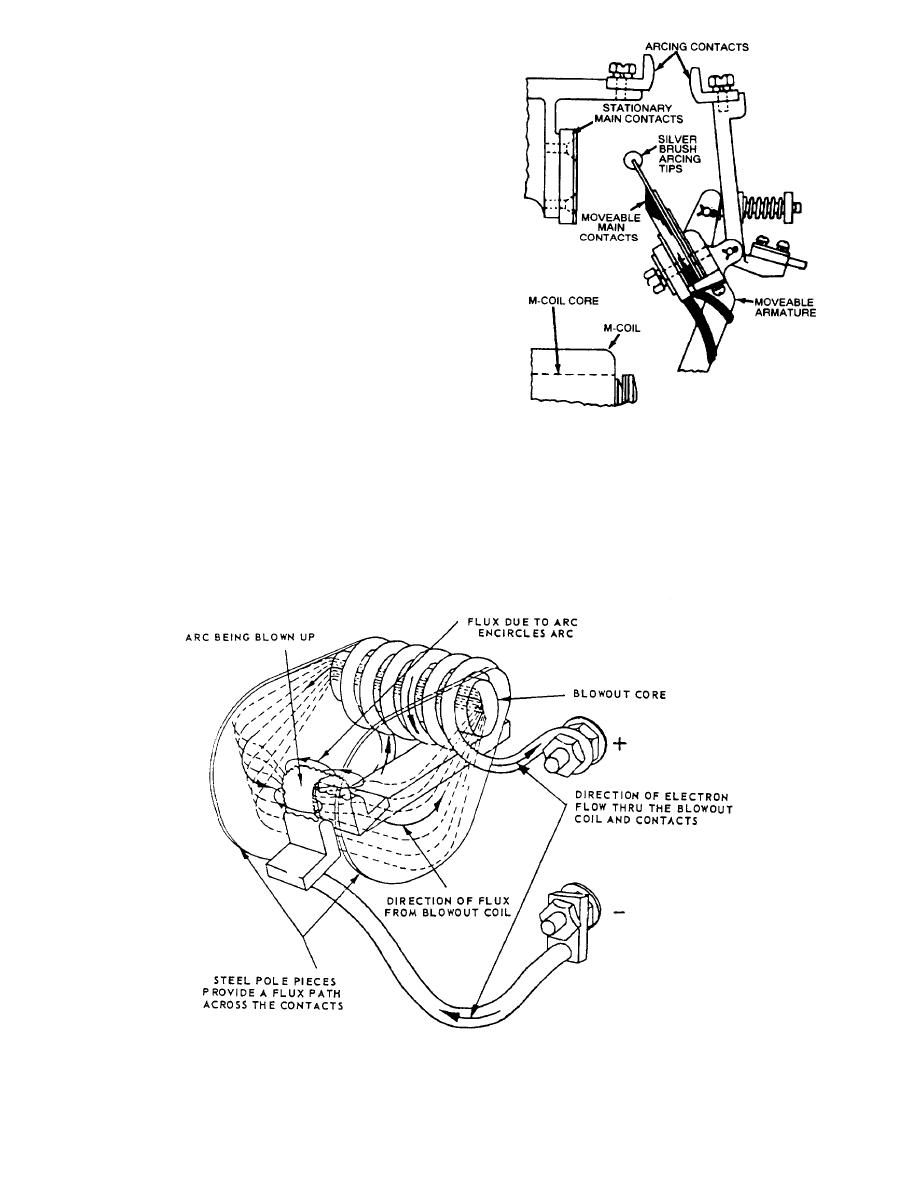

Figure 1-18.-Action of a magnetic blowout coil. |

|

||

| ||||||||||

|

|

blowout coils overcome this condition by providing a

magnetic field, which pushes the arc away from the

contact area.

The magnetic blowout operation is shown in fig-

ure 1-18. It is important that the fluxes remain in the

proper relationship. Otherwise, if the direction of the

current is changed, the direction of the blowout flux will

be reversed and the arc will actually be pulled into the

space between the contacts.

When the direction of electron flow and flux areas

shown in figure 1-18, the blowout force is upward. The

blowout effect varies with the magnitude of the current

and with the blowout flux. The blowout coil should be

chosen to match the current so the correct amount of

flux may be obtained. The blowout flux across the arc

gap is concentrated by the magnetic path provided by

the steel core in the blowout coil and by the steel pole

pieces extending from the core to either side of the gap.

Figure 1-19.Detailed view of arcing contacts.

Arcing Contacts

Shunt-type contractors will handle up to 600

amperes at 230 volts. The blowout shield has been

removed in this detailed view. The diagram shows the

The shunt contactor shown in figure 1-19 uses a

main sections of the contactor. The arcing contacts (1)

second set of contacts (1) to reduce the amount of arcing

are made of rolled copper with a heavy protective coat-

across the main contacts (5 and 6) when closing. The

ing of cadmium. These contacts are self-cleaning be-

numbers that are in parentheses are indicated on the

figure.

cause of the sliding or wiping action following the initial

Figure 1-18.-Action of a magnetic blowout coil.

1-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |