|

|||

|

Page Title:

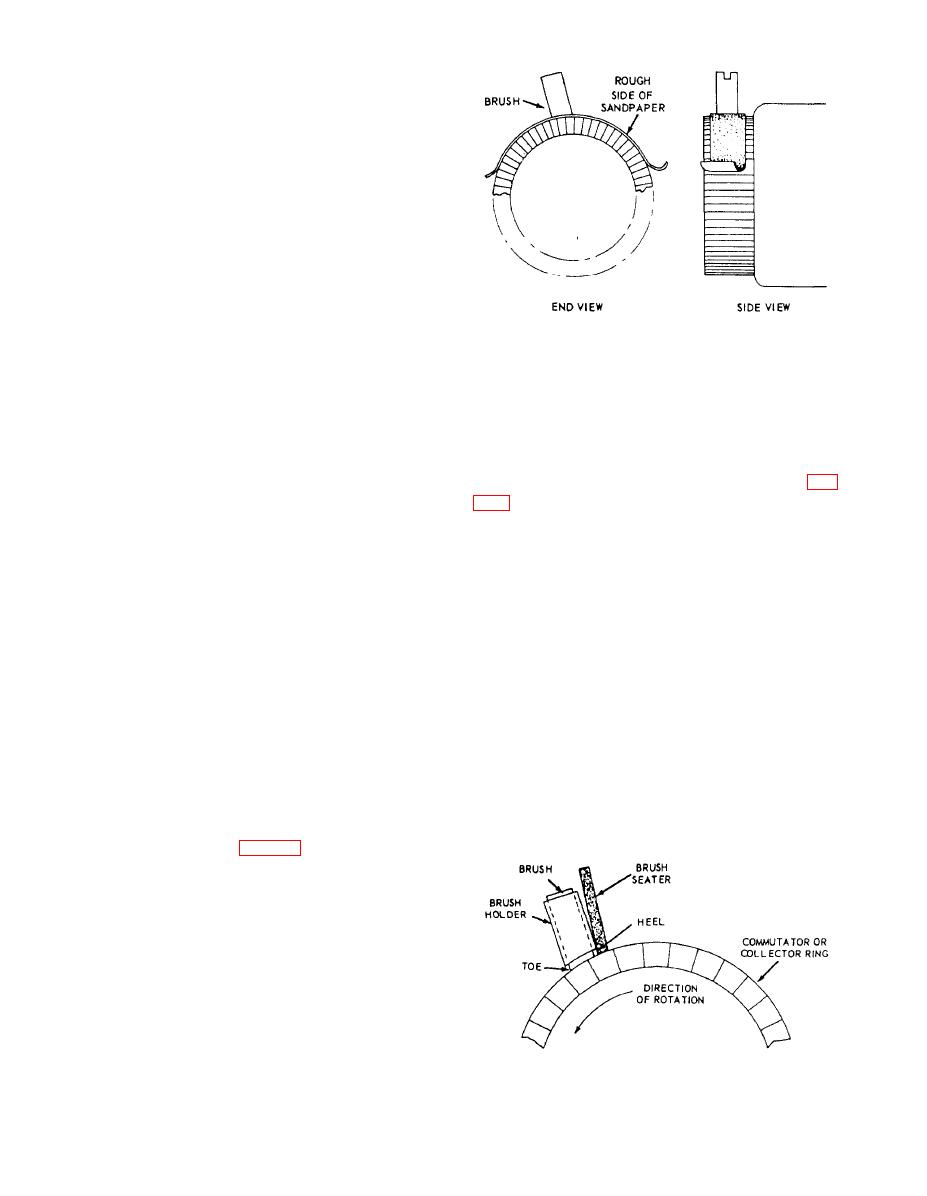

Figure 3-11.--Method of sanding brushes. |

|

||

| ||||||||||

|

|

from between the brush and commutator without

offering resistance. This reading divided by the

contact area may be considered to be the spring

operating pressure.

The toes of all brushes of each brush stud should

line up with each other and with the edge of one

commutator segment.

The brushes should be evenly spaced around the

commutator. To check brush spacing, wrap a strip of

paper around the commutator and mark the paper

where the paper laps. Remove the paper from the

commutator, cut at the lap, and fold or mark the paper

into as many equal parts as there are brush studs.

Replace the paper on the commutator, and adjust the

brush holders so that the toes of the brushes are at the

creases or marks.

start the machine. Press a brush securely against the

All brush holders should be the same distance

commutator by using a stick of insulating material or

from the commutator, not more than one-eighth inch,

by increasing the brush spring tension to its maximum

nor less than one-sixteenth inch. A brush holder must

value. Touch the brush seater lightly to the

be free of all burrs that might interfere with the free

commutator, exactly at the heel of the brush (fig.

movement of the brush in the holder. Burrs are easily

removed with a fine file.

seater will be carried under the brush. You must hold

SEATING.-- Accurate seating of the brushes

the brush seater behind each brush, applying the seater

must be ensured where their surfaces contact the

for a second or two, depending on brush size. Do not

commutator. Sandpaper and a brush seater are the best

hold the seater steadily against the commutator

tools to accomplish a true seat.

because it will wear away too rapidly and produce too

Disconnect all power from the machine. Before

much dust. After seating one or two brushes, examine

using sandpaper to seat the brushes, you must take

them to see if the seater is being applied long enough

every precaution to ensure that the machine will not

to give a full seat. After seating the brush, if white dust

be inadvertently started.

is plainly visible on the seat, you have applied

Lift the brushes to be fitted, and insert (sand side

insufficient pressure to the brush, or applied the brush

up) a strip of fine sandpaper (No. 1), about the width

seater too heavily or too far from the brush. Be careful

of the commutator, between the brushes and the

not to remove the copper oxide film from the

commutator. With the sandpaper held tightly against

commutator surface. If you remove this film, you must

the commutator surface to conform with the curvature

restore it.

and the brushes held down by normal spring pressure,

pull the sandpaper in the direction of the normal

rotation of the machine (fig. 3-11), When returning the

sandpaper for another pull, lift the brushes. Repeat this

operation until the seat of the brush is accurate.

Always finish with a finer grade of sandpaper (No. 0).

You need a vacuum cleaner for removing dust while

sanding. After sanding, thoroughly clean the

commutator and windings to remove all carbon dust.

The use of a brush seater will further improve the

fit obtained by sanding. A brush seater consists of a

mildly abrasive material loosely bonded into a stick

about 5 inches long. To use a brush seater to seat the

brushes, install the brushes in the brush holders and

3-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |