|

|||

|

Page Title:

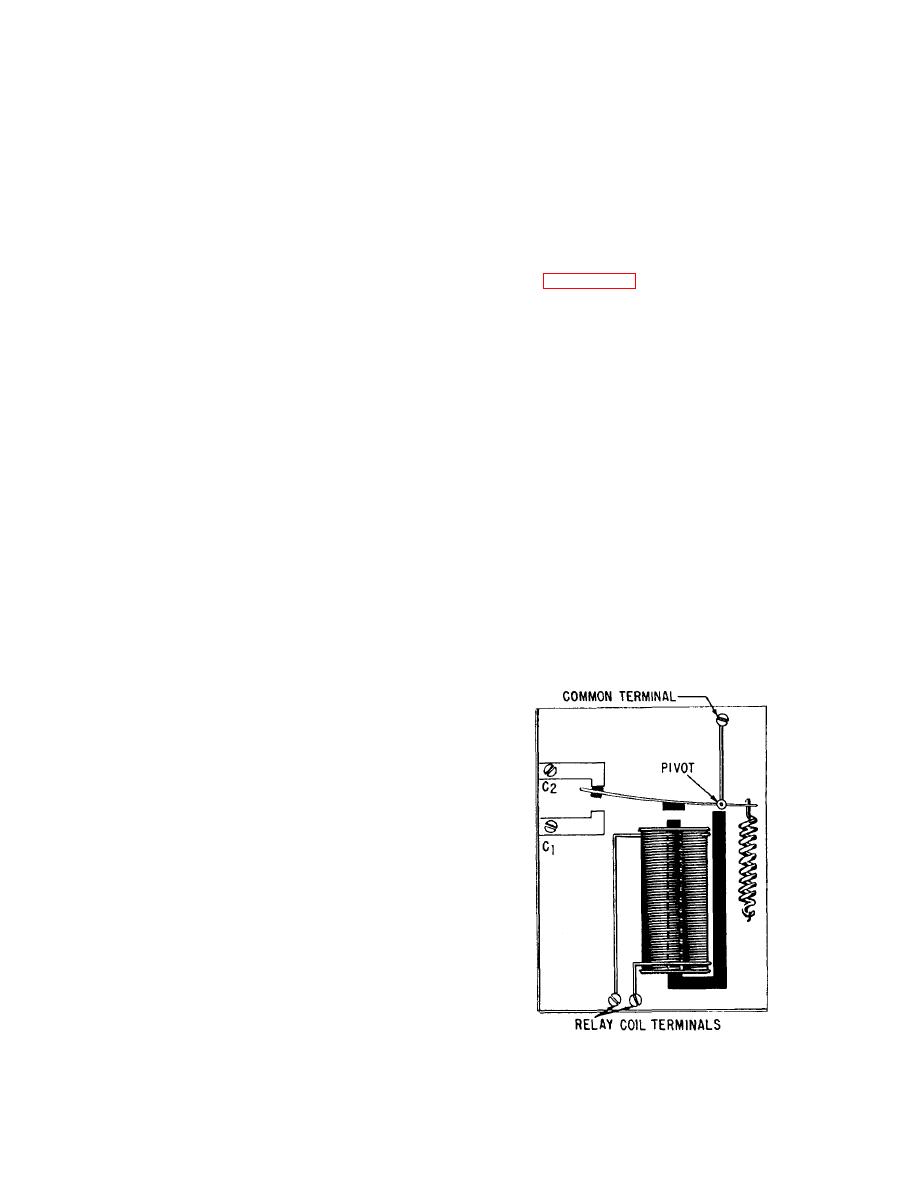

Figure 2-20.--Relay construction. |

|

||

| ||||||||||

|

|

to the contacts. Use a burnishing tool for dressing

shorted turn acts as the secondary of a transformer, the

small light contacts.

primary of which is the relay operating coil. The

current in the shorted turn is out of phase with the

Clean burned copper contacts with fine sandpaper.

current of the operating coil because the copper ring

Do not use emery cloth. Badly burned contacts should

has low-inductive reactance. Thus, when the operating

be replaced. Always replace contacts in pairs, rather

coil flux is zero, the flux produced by the shorted coil

than replacing a single contact.

is different from zero, and the tendency of the relay to

Silver contacts require very little maintenance.

chatter is reduced.

Removal of the tarnish that forms on silver contacts

due to arcing is no longer recommended, as this

In general, a relay consists of a magnetic core and

blackened condition improves the operation of the

associated coil, contacts, springs, armature, and the

contacts.

mounting. Figure 2-20 illustrates the fundamental

construction of a relay. When the coil is energized, the

When replacing a switch, take great care in

flow of current through the coil creates a strong

tagging the leads to ensure proper replacement. Close

magnetic field that pulls the armature downward to

supervision and proper checkout by an electrical petty

contact C1, completing the circuit from the common

officer can ensure against personal injury and

terminal to C1. At the same time the circuit to contact

equipment damage.

C2 is opened.

Relays are classified according to their use as

RELAYS

control relays or power relays.

Relays are electrically operated switches. The

CONTROL RELAYS

operating coil can be connected in series with a supply

line to the load or shunted across the line.

Control relays are usually known simply as relays.

The coil design is influenced by the manner in

They are frequently used in the control of low-power

which the relay is used. When the relay is designed for

circuits or other relays, although they also have many

series connection, the coil is usually wound with a

other uses. Where multipole relays are used, several

fairly small number of turns of large wire because the

circuits may be controlled simultaneously. In

load current will be flowing through the winding.

automatic relaying circuits, a small electrical signal

When the relay is designed for shunt connection, the

coil is wound with a large number of turns of small

wire, which will increase the resistance and thus lower

the current through the coil.

Because the contacts of relays may open or close

when energized, they can be used as protective devices

or control devices or both simultaneously.

The basic difference between ac and dc relays lies

in the armature and magnet core construction. The

armature and magnet cores of an ac relay are made up

of laminations, and those of a dc relay are of solid

material. The use of laminations in an ac relay reduces

strap or ring (called a shorted turn) is placed near the

end of the pole piece of an ac relay to reduce chatter

during operation. Because the ac is going through a

peak, dropping to zero, going through a peak in the

opposite direction, and then dropping to zero again

during each complete cycle, the coil tends to release

the armature each time the current drops to zero and

attracts the armature each time it reaches a peak. The

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |